Page 66 - E BOOK ENGINE MECHANICAL M2

P. 66

4. SERVICE POINTS OF 4D56 ENGINE COMPONENT

5. Align the fuel injection pipe centre axis with the other

side components (fuel injector assembly and common

rail assembly) centre axis to install the fuel injection

pipe. Then, tighten the flare nut temporarily until the tip

of pipe (seal surface) contacts with the other side com-

ponents.

When the fuel injection pipe is installed, tighten the

Note flare nut while shaking the pipe lightly to align the

centre axis of both components.

6. Using special tool Fuel injection pipe wrench

(MB992188), install injection pipe assembly No.1 to

No.4. Tighten to the specified torque of 35 ± 5 Nm the

flare nuts of the fuel injection pipe No.1 to No.4 at injec-

tor side.

Fig. 4-13

7. Using special tool Fuel injection pipe wrench

(MB992188), install injection pipe assembly No.1 to

No.4. Tighten to the specified torque of 35 ± 5 Nm the

flare nuts of the fuel injection pipe No.1 to No.4 at com-

mon rail side.

8. Tighten the common rail to the specified torque of 24

± 4 Nm.

9. Tighten to the specified torque of 20 ± 2 Nm the eye

bolt and the fuel return gasket located at the common

rail side.

10. Tighten the fuel return pipe to the specified torque of

Fig. 4-14 10 ± 2 Nm.

11. Tighten to the specified torque of 10 ± 2 Nm the

bolts of the fuel injection pipe No.1 to No.4.

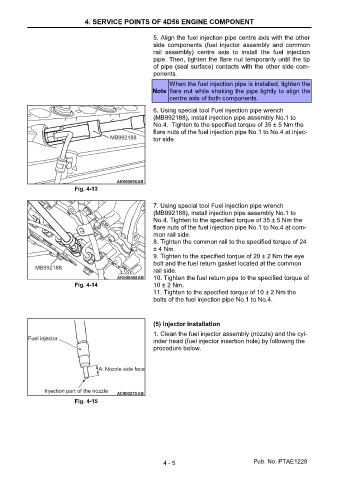

(5) Injector Installation

1. Clean the fuel injector assembly (nozzle) and the cyl-

inder head (fuel injector insertion hole) by following the

procedure below.

Fig. 4-15

4 - 5 Pub. No. PTAE1228