Page 65 - E BOOK ENGINE MECHANICAL M2

P. 65

4. SERVICE POINTS OF 4D56 ENGINE COMPONENT

(4) Common Rail Installation

The high pressure pipe between injectors and common rail may reinstalled up to five

times. In order to keep count, record the number of reinstallation history on the service

booklet by adding "1" to the previous one. Use a new injection pipe when the pipe is re-

moved the 6th time, and start a new count, or when the injector or common rail is re-

placed. In this case, record "a new injection pipe, the number of the reinstallation histo-

ries is zero" on the service booklet.

If a fuel leak is present in the fuel injection pipe, even if it has only being removed once,

Caution do not reuse it and replace with a new one.

If the fuel injector assembly, common rail assembly or supply pump assembly is re-

placed, the sealing contact surface between the fuel injection pipe and the other side

component has to be replaced. Do not reuse the fuel injection pipe and fuel supply

pump pipe and replace with a new one.

When the injection pipe is reinstalled, confirm there is no foreign material on the sealing

surface or in the pipe and then install it not to deviate from the axis, fitting the seal sur-

face.

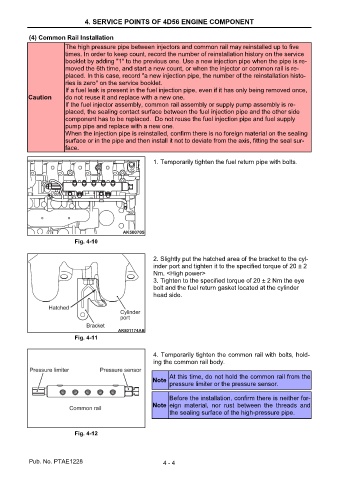

1. Temporarily tighten the fuel return pipe with bolts.

Fig. 4-10

2. Slightly put the hatched area of the bracket to the cyl-

inder port and tighten it to the specified torque of 20 ± 2

Nm. <High power>

3. Tighten to the specified torque of 20 ± 2 Nm the eye

bolt and the fuel return gasket located at the cylinder

head side.

Fig. 4-11

4. Temporarily tighten the common rail with bolts, hold-

ing the common rail body.

At this time, do not hold the common rail from the

Note

pressure limiter or the pressure sensor.

Before the installation, confirm there is neither for-

Note eign material, nor rust between the threads and

the sealing surface of the high-pressure pipe.

Fig. 4-12

Pub. No. PTAE1228 4 - 4