Page 1303 - YG 2019

P. 1303

TECHNICAL

DATA SUPER CUTTING END MILLS

ROTARY

ROTARY

Trouble Occurrences of trouble Countermeasures

•Surface is good but rough 1. Decrease feed

2. In case using 2 flute, increase to 4 flute

•Small chip welding 1. Increase cutting speed TOOL HOLDERS

2. Utilize wet cutting air blow(ample supply) TOOL HOLDERS

3. Carry out fine honing

4. Up cut → Down cut

Inferior finished surface 5. Increase feed or enlarge finish allowance

•With transverse streaks 1. Carry out fine honing

2. Use water insoluble cutting fluid

3. Down cut → Up cut

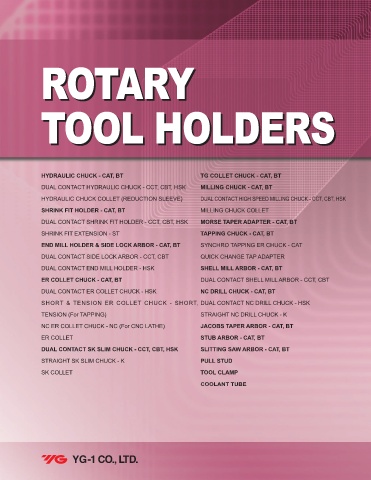

HYDRAULIC CHUCK - CAT, BT TG COLLET CHUCK - CAT, BT

•Signs of excessive cutting 1. Reduce finishing depth of cut

2. Increase cutting speed DUAL CONTACT HYDRAULIC CHUCK - CCT, CBT, HSK MILLING CHUCK - CAT, BT

3. Reduce feed

HYDRAULIC CHUCK COLLET (REDUCTION SLEEVE) DUAL CONTACT HIGH SPEED MILLING CHUCK - CCT, CBT, HSK

•Finish dimensions are 1. Up cut → Down cut SHRINK FIT HOLDER - CAT, BT MILLING CHUCK COLLET

on minus side 2. Reduce finishing depth of cut

3. Replace chuck or collet DUAL CONTACT SHRINK FIT HOLDER - CCT, CBT, HSK MORSE TAPER ADAPTER - CAT, BT

4. Reduce projection amount

5. Increase cutting speed SHRINK FIT EXTENSION - ST TAPPING CHUCK - CAT, BT

Poor machining END MILL HOLDER & SIDE LOCK ARBOR - CAT, BT SYNCHRO TAPPING ER CHUCK - CAT

accuracy •Poor perpendicularity 1. Reduce finishing depth of cut

2. Replace chuck or collet

3. Reduce projection amount DUAL CONTACT SIDE LOCK ARBOR - CCT, CBT QUICK CHANGE TAP ADAPTER

4. Increase cutting speed DUAL CONTACT END MILL HOLDER - HSK SHELL MILL ARBOR - CAT, BT

5. 2Flute → 4 Flute

6. Reduce feed ER COLLET CHUCK - CAT, BT DUAL CONTACT SHELL MILL ARBOR - CCT, CBT

7. Check wear rate → Replace tool

DUAL CONTACT ER COLLET CHUCK - HSK NC DRILL CHUCK - CAT, BT

1. Increase feed rate(in case over 0.05 mm/Zahn, try reducing)

2. Change cutting speed SHORT & TENSION ER COLLET CHUCK - SHORT, DUAL CONTACT NC DRILL CHUCK - HSK

Chattering 3. Replace chuck or collet

4. Reduce projection amount TENSION (For TAPPING) STRAIGHT NC DRILL CHUCK - K

5. Use 2 flute cutter for rough cutting and 4 flute for finishing NC ER COLLET CHUCK - NC (For CNC LATHE) JACOBS TAPER ARBOR - CAT, BT

6. Down cut → Up cut

ER COLLET STUB ARBOR - CAT, BT

DUAL CONTACT SK SLIM CHUCK - CCT, CBT, HSK SLITTING SAW ARBOR - CAT, BT

STRAIGHT SK SLIM CHUCK - K PULL STUD

SK COLLET TOOL CLAMP

COOLANT TUBE

1304 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com