Page 1299 - YG 2019

P. 1299

TECHNICAL TECHNICAL

DATA SUPER CUTTING END MILLS DATA SUPER CUTTING END MILLS

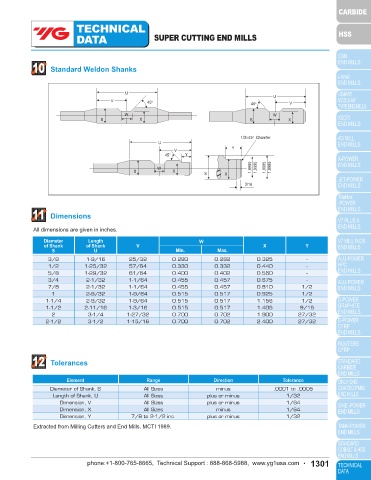

8 Resharpening End Teeth A. Use Plain B. Use Plain 10 Standard Weldon Shanks

Wheel

Wheel

End Mill

The three necessary operations and one Notch Angle may be

option feature, along with setup suggestions traversed

are shown in Fig.5 A to D in each drawing, the into wheel U U

in this direction

shaded area indicates the surface being V 45° 45° V

ground. End Mill may

be traversed Or passed under W W

into wheel in the wheel Or passed under S X S X

this direction the wheel

1st Operation Notch slightly beyond center 2nd Operation - Secondary clear end 1/3×45° Chamfer

U

V Y

C. 5° ~12° primary D. Use Plain 45° Y

1/2~5 End end relief Wheel

concavity Traverse W 1.9990 1.9995 1.9995 1.9999

end mill S X

Use Cup under the S X

Wheel

wheel

3/16

Or end mill

End Mill may be

may be traversed

traversed into wheel

under end Or wheel may be traversed in this direction

face wheel across end of end mill 11 Dimensions

(optional)

3rd Operation-Primay relieve end 4th Operation-Clear and at junction All dimensions are given in inches.

of Secondary clear & notch

Fig 5. PROCEDURE FOR SHARPENING END OF 2 FLUTE SQUARE END MILLS Diameter Length W

of Shank of Shank V Min. Max. X Y

U

S

9 9 Inspection 3/8 1-9/16 25/32 0.280 0.282 0.325 -

1/2 1-25/32 57/64 0.330 0.332 0.440 -

The inspection is calculated by using the formula shown in Table1. 5/8 1-29/32 61/64 0.400 0.402 0.560 -

Procedure To Check 3/4 2-1/32 1-1/64 0.455 0.457 0.675 -

Radial Relief Angles 7/8 2-1/32 1-1/64 0.455 0.457 0.810 1/2

With Indicators. 1 2-9/32 1-9/64 0.515 0.517 0.925 1/2

1-1/4 2-9/32 1-9/64 0.515 0.517 1.156 1/2

1. Mount the cutter to rotate freely with no end movement. 1-1/2 2-11/16 1-3/16 0.515 0.517 1.406 9/16

2. Adjust the sharp pointed indicator to bear at the very tip of the cutting edge, pointing in a radial line, 2 3-1/4 1-27/32 0.700 0.702 1.900 27/32

shown in Figure6 2-1/2 3-1/2 1-15/16 0.700 0.702 2.400 27/32

3. Roll the cutter the tabuleted amount gives under “checking distance” using the second indicator as

control.

4. Consult chart for amount of drop for the particular diameter and relief angle.

Radial Relief Peripheral Cutting Edge Cutting Angle

12 Tolerances

Primary

Land Width Element Range Direction Tolerance

Diameter of Shank, S All Sizes minus .0001 to .0005

α1

Indicator Drop α2 Length of Shank, U All Sizes plus or minus 1/32

Dimension, V All Sizes plus or minus 1/64

Dimension, X All Sizes minus 1/64

Distance

Dimension, Y 7/8 to 2-1/2 inc. plus or minus 1/32

Checking

Checking

Distance Indicator Drop Extracted from Milling Cutters and End Mills. MCTI 1989.

Fig. 6. Indicator Set-Up for Checking

1300 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1301