Page 1301 - YG 2019

P. 1301

TECHNICAL TECHNICAL

DATA SUPER CUTTING END MILLS DATA SUPER CUTTING END MILLS

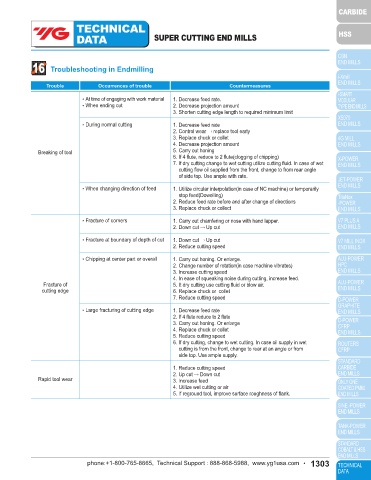

13 Combination Shanks for End Mills 16 Troubleshooting in Endmilling

Right hand End Mill shank shown. For Trouble Occurrences of trouble Countermeasures

left hand End Mills flat “F” and pin

groove “K” should be located 180° from •At time of engaging with work material 1. Decrease feed rate.

that shown, maintaining 12° relationship G •When ending cut 2. Decrease projection amount

of flat “F” and groove “K” 3. Shorten cutting edge length to required minimum limit

K F 45° •During normal cutting 1. Decrease feed rate

E 2. Control wear → replace tool early

L 3. Replace chuck or collet

B 4. Decrease projection amount

Breaking of tool 5. Carry out honing

90° 1/2K H C 45° 6. If 4 flute, reduce to 2 flute(clogging of chipping)

7. If dry cutting change to wet cutting utilize cutting fluid. In case of wet

cutting flow oil supplied from the front, change to from rear angle

A J D of side top. Use ample with rate.

•When changing direction of feed 1. Utilize circular interpolation(in case of NC machine) or temporarily

.015 stop feed(Dowelling)

M CENTRAL WITH “K”

12° 2. Reduce feed rate before and after change of directions

3. Replace chuck or collect

14 Dimensions

•Fracture of corners 1. Carry out chamfering or nose with hand lapper.

All dimensions are given in inches. 2. Down cut → Up cut

Diameter Length •Fracture at boundary of depth of cut 1. Down cut → Up cut

of Shank of Shank B C D E F G H J K M 2. Reduce cutting speed

A L

1-1/2 2-11/16 1-3/16 0.515 1.406 1-1/2 0.515 1.371 9/16 1.302 0.377 7/16 •Chipping at center part or overall 1. Carry out honing. Or enlarge.

2 3-1/4 1-23/32 0.700 1.900 1-3/4 0.700 1.809 5/8 1.772 0.440 1/2 2. Change number of rotation(in case machine vibrates)

2-1/2 3-1/2 1-15/16 0.700 2.400 2 0.700 2.312 3/4 2.245 0.503 9/16 3. Increase cutting speed

4. In ease of squeaking noise during cutting, increase feed.

Fracture of 5. It dry cutting use cutting fluid or blow air.

cutting edge 6. Replace chuck or collet

7. Reduce cutting speed

15 Tolerances

•Large fracturing of cutting edge 1. Decrease feed rate

2. If 4 flute reduce to 2 flute

Element Direction Tolerance

3. Carry out honing. Or enlarge

Diameter of Shank, A minus .0001 to .0005 4. Replace chuck or collet

Length of Shank, L plus or minus 1/32 5. Reduce cutting speed

Dimension, B plus or minus 1/64 6. If dry cutting, change to wet cutting. In case oil supply in wet

Dimension, C plus .002 cutting is from the front, change to rear at an angle or from

Dimension, D minus 1/64 side top. Use ample supply.

Dimension, E plus or minus 1/64

Dimension, F plus or minus .005 1. Reduce cutting speed

Dimension, G minus 1/64 Rapid tool wear 2. Up cut → Down cut

3. Increase feed

Dimension, H plus 1/64 4. Utilize wet cutting or air

Dimension, J plus or minus .002 5. If reground tool, improve surface roughness of flank.

Dimension, K plus .003

Extracted from Milling Cutters and End Mills. MCTI 1989.

1302 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1303