Page 881 - YG 2019

P. 881

X-POWER X-POWER

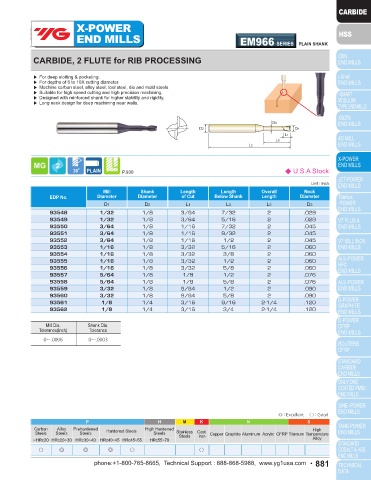

END MILLS EM662 SERIES PLAIN SHANK END MILLS EM966 SERIES PLAIN SHANK

CARBIDE, MULTI FLUTE 20° HELIX LONG LENGTH CARBIDE, 2 FLUTE for RIB PROCESSING

FINE PITCH ROUGHING BALL NOSE

▶ Designed to machine tool steel, alloy steel, mold steel and other high hardened materials. ▶ For deep slotting & pocketing.

▶ High velocity milling of hardened steels. ▶ For depths of 6 to 10X cutting diameter.

▶ For dry and wet milling. ▶ Machine carbon steel, alloy steel, tool steel, die and mold steels.

▶ Fast chip ejection. ▶ Suitable for high speed cutting and high precision machining.

▶ Designed with reinforced shank for higher stability and rigidity.

▶ Long neck design for deep machining near walls.

R

↙

D3

D2 D1

L1

L3

L2

P.930 ◆ U.S.A Stock P.930 ◆ U.S.A Stock

Unit : Inch Unit : Inch

Radius of Mill Shank Length Length Overall Neck

Mill

Shank

EDP No. Ball Nose Diameter Diameter Length Overall No. of EDP No. Diameter Diameter of Cut Below Shank Length Diameter

Flute

Length

of Cut

R (±.001) D1 D2 L1 L3 L2 D3

93263 R1/8 1/4 1/4 3/4 2-1/2 3 93548 1/32 1/8 3/64 7/32 2 .029

93264 R5/32 5/16 5/16 3/4 2-1/2 3 93549 1/32 1/8 3/64 5/16 2 .029

93265 R3/16 3/8 3/8 7/8 2-1/2 3 93550 3/64 1/8 1/16 7/32 2 .045

93266 R1/4 1/2 1/2 1 3 4 93551 3/64 1/8 1/16 9/32 2 .045

93267 R5/16 5/8 5/8 1-1/4 3-1/2 4 93552 3/64 1/8 1/16 1/2 2 .045

93268 R3/8 3/4 3/4 1-5/8 4 4 93553 1/16 1/8 3/32 5/16 2 .060

93269 R1/2 1 1 1-3/4 4 5 93554 1/16 1/8 3/32 3/8 2 .060

93555 1/16 1/8 3/32 1/2 2 .060

Mill Dia. Mill Dia. Shank Dia. 93556 1/16 1/8 3/32 5/8 2 .060

(inch) Tolerance(inch) Tolerance 93557 5/64 1/8 1/8 1/2 2 .076

1/4~3/8 0 ~ -.0022 93558 5/64 1/8 1/8 5/8 2 .076

93559 3/32 1/8 9/64 1/2 2 .090

1/2~5/8 0 ~ -.0027 0 ~ -.0003

93560 3/32 1/8 9/64 5/8 2 .090

3/4~1 0 ~ -.0033

93561 1/8 1/4 3/16 9/16 2-1/4 .120

93562 1/8 1/4 3/16 3/4 2-1/4 .120

Mill Dia. Shank Dia.

Tolerance(inch) Tolerance

0~-.0006 0~-.0003

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Iron

Steels

Steels

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ○ ◎ ◎ ◎ ○ ○

880 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 881