Page 883 - YG 2019

P. 883

X-POWER X-POWER

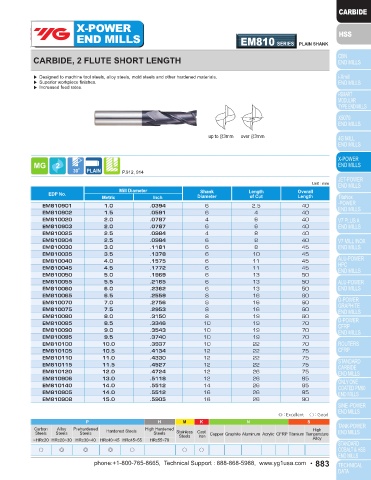

END MILLS EM967 SERIES PLAIN SHANK END MILLS EM810 SERIES PLAIN SHANK

CARBIDE, 2 FLUTE BALL NOSE for RIB PROCESSING CARBIDE, 2 FLUTE SHORT LENGTH

▶ For 3-D milling, deep slotting and pocketing. ▶ Designed to machine tool steels, alloy steels, mold steels and other hardened materials.

▶ For depths of 6 to 10X cutting diameter. ▶ Superior workpiece finishes.

▶ Machine carbon steel, alloy steel, tool steel, die and mold steels. ▶ Increased feed rates.

▶ Suitable for high speed cutting and high precision machining.

▶ Designed with reinforced shank for higher stability and rigidity.

▶ Long neck design for deep machining near walls.

R R

↙ D3

D2 D1

L1 up to Ø3mm over Ø3mm

L3

L2

P.931 ◆ U.S.A Stock P.912, 914

Unit : Inch Unit : mm

Radius of Mill Shank Length Length Overall Neck EDP No. Mill Diameter Shank Length Overall

EDP No. Ball Nose Diameter Diameter of Cut Below Shank Length Diameter Metric Inch Diameter of Cut Length

R (±.0005) D1 D2 L1 L3 L2 D3 EM810901 1.0 .0394 6 2.5 40

93563 R1/64 1/32 1/8 3/64 7/32 2 .029 EM810902 1.5 .0591 6 4 40

93564 R1/64 1/32 1/8 3/64 5/16 2 .029 EM810020 2.0 .0787 4 6 40

93565 R.0234 3/64 1/8 1/16 7/32 2 .045 EM810903 2.0 .0787 6 6 40

93566 R.0234 3/64 1/8 1/16 9/32 2 .045 EM810025 2.5 .0984 4 8 40

93567 R.0234 3/64 1/8 1/16 1/2 2 .045 EM810904 2.5 .0984 6 8 40

93568 R1/32 1/16 1/8 3/32 5/16 2 .060 EM810030 3.0 .1181 6 8 45

93569 R1/32 1/16 1/8 3/32 1/2 2 .060 EM810035 3.5 .1378 6 10 45

93570 R1/32 1/16 1/8 3/32 5/8 2 .060 EM810040 4.0 .1575 6 11 45

93571 R.0391 5/64 1/8 1/8 5/16 2 .076 EM810045 4.5 .1772 6 11 45

93572 R.0391 5/64 1/8 1/8 5/8 2 .076 EM810050 5.0 .1969 6 13 50

93573 R.0391 5/64 1/8 1/8 3/4 2 .076 EM810055 5.5 .2165 6 13 50

93574 R3/64 3/32 1/8 9/64 5/8 2 .090 EM810060 6.0 .2362 6 13 50

93575 R3/64 3/32 1/8 9/64 3/4 2 .090 EM810065 6.5 .2559 8 16 60

93576 R1/16 1/8 1/4 3/16 5/8 2-1/4 .120 EM810070 7.0 .2756 8 16 60

93577 R1/16 1/8 1/4 3/16 3/4 2-1/4 .120 EM810075 7.5 .2953 8 16 60

EM810080 8.0 .3150 8 19 60

Mill Dia. Shank Dia. EM810085 8.5 .3346 10 19 70

Tolerance(inch) Tolerance EM810090 9.0 .3543 10 19 70

EM810095 9.5 .3740 10 19 70

0~-.0006 0~-.0003

EM810100 10.0 .3937 10 22 70

EM810105 10.5 .4134 12 22 75

EM810110 11.0 .4330 12 22 75

EM810115 11.5 .4527 12 22 75

EM810120 12.0 .4724 12 26 75

EM810906 13.0 .5118 12 26 85

EM810140 14.0 .5512 14 26 85

EM810905 14.0 .5512 16 26 85

EM810908 15.0 .5905 16 26 90

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

Iron

Steels

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ○ ◎ ◎ ◎ ○ ○ ○

882 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 883