Page 453 - CarrLaneCatalog_2019ed-c.pdf

P. 453

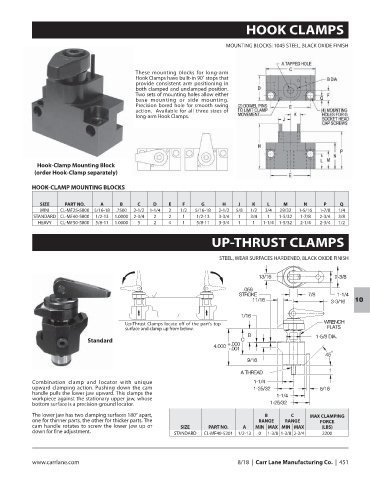

HOOK CLAMPS

MOUNTING BLOCKS: 1045 STEEL, BLACK OXIDE FINISH

These mounting blocks for long-arm

Hook Clamps have built-in 90˚ stops that

provide consistent arm positioning in

both clamped and unclamped position.

Two sets of mounting holes allow either

base mounting or side mounting.

Precision bored hole for smooth swing

action. Available for all three sizes of

long-arm Hook Clamps.

Hook-Clamp Mounting Block

(order Hook-Clamp separately)

HOOK-CLAMP MOUNTING BLOCKS

SIZE PART NO. A B C D E F G H J K L M N P Q

MINI CL-MF25-5800 5/16-18 .7500 2-1/2 1-1/4 2 1/2 5/16-18 2-1/2 5/8 1/2 3/4 29/32 1-5/16 1-7/8 1/4

STANDARD CL-MF40-5800 1/2-13 1.0000 2-3/4 2 2 1 1/2-13 3-3/4 1 3/4 1 1-5/32 1-7/8 2-3/4 3/8

HEAVY CL-MF50-5800 5/8-11 1.0000 5 2 4 1 5/8-11 3-3/4 1 1 1-1/4 1-5/32 2-1/4 2-3/4 1/2

UP-THRUST CLAMPS

STEEL, WEAR SURFACES HARDENED, BLACK OXIDE FINISH

10

Up-Thrust Clamps locate off of the part’s top

surface and clamp up from below.

Standard

Combination clamp and locator with unique

upward clamping action. Pushing down the cam

handle pulls the lower jaw upward. This clamps the

workpiece against the stationary upper jaw, whose

bottom surface is a precision-ground locator.

The lower jaw has two clamping surfaces 180° apart, B C MAX CLAMPING

one for thinner parts, the other for thicker parts. The RANGE RANGE FORCE

cam handle rotates to screw the lower jaw up or SIZE PART NO. A MIN MAX MIN MAX (LBS)

down for fine adjustment. STANDARD CL-MF40-5301 1/2-13 0 1-3/8 1-3/8 2-3/4 2200

www.carrlane.com 8/18 | Carr Lane Manufacturing Co. | 451