Page 474 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 474

The City & Guilds Textbook: Plumbing Book 1

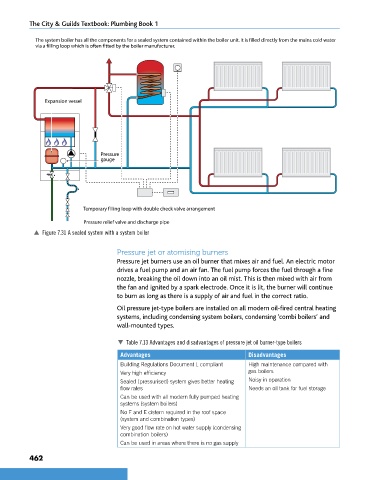

The system boiler has all the components for a sealed system contained within the boiler unit. It is filled directly from the mains cold water

via a filling loop which is often fitted by the boiler manufacturer.

Expansion vessel

Pressure

gauge

Temporary filling loop with double check valve arrangement

Pressure relief valve and discharge pipe

p Figure 7.31 A sealed system with a system boiler

Pressure jet or atomising burners

Pressure jet burners use an oil burner that mixes air and fuel. An electric motor

drives a fuel pump and an air fan. The fuel pump forces the fuel through a fine

nozzle, breaking the oil down into an oil mist. This is then mixed with air from

the fan and ignited by a spark electrode. Once it is lit, the burner will continue

to burn as long as there is a supply of air and fuel in the correct ratio.

Oil pressure jet-type boilers are installed on all modern oil-fired central heating

systems, including condensing system boilers, condensing ‘combi boilers’ and

wall-mounted types.

Table 7.13 Advantages and disadvantages of pressure jet oil burner-type boilers

Advantages Disadvantages

Building Regulations Document L compliant High maintenance compared with

Very high efficiency gas boilers

Sealed (pressurised) system gives better heating Noisy in operation

flow rates Needs an oil tank for fuel storage

Can be used with all modern fully pumped heating

systems (system boilers)

No F and E cistern required in the roof space

(system and combination types)

Very good flow rate on hot water supply (condensing

combination boilers)

Can be used in areas where there is no gas supply

462

9781510416482.indb 462 29/03/19 9:03 PM