Page 478 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 478

The City & Guilds Textbook: Plumbing Book 1

Fresh Fresh

air inlet air inlet Fan

Flue

gases

outlet

Fresh

air inlet

Flue

gases

outlet

Gas burner

Gas burner

Room sealed

boiler casing

Room sealed

boiler casing

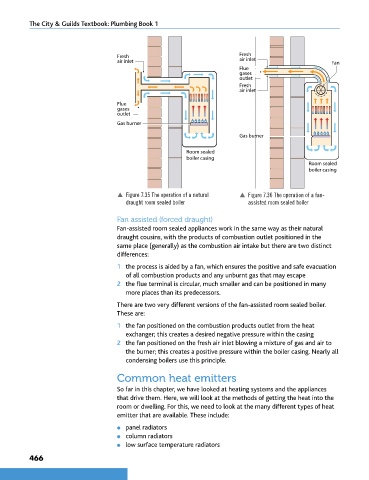

p Figure 7.35 The operation of a natural p Figure 7.36 The operation of a fan-

draught room sealed boiler assisted room sealed boiler

Fan assisted (forced draught)

Fan-assisted room sealed appliances work in the same way as their natural

draught cousins, with the products of combustion outlet positioned in the

same place (generally) as the combustion air intake but there are two distinct

differences:

1 the process is aided by a fan, which ensures the positive and safe evacuation

of all combustion products and any unburnt gas that may escape

2 the flue terminal is circular, much smaller and can be positioned in many

more places than its predecessors.

There are two very different versions of the fan-assisted room sealed boiler.

These are:

1 the fan positioned on the combustion products outlet from the heat

exchanger; this creates a desired negative pressure within the casing

2 the fan positioned on the fresh air inlet blowing a mixture of gas and air to

the burner; this creates a positive pressure within the boiler casing. Nearly all

condensing boilers use this principle.

Common heat emitters

So far in this chapter, we have looked at heating systems and the appliances

that drive them. Here, we will look at the methods of getting the heat into the

room or dwelling. For this, we need to look at the many different types of heat

emitter that are available. These include:

l panel radiators

l column radiators

l low surface temperature radiators

466

9781510416482.indb 466 29/03/19 9:03 PM