Page 156 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 156

140 Applied Process Design for Chemical and Petrochemical Plants

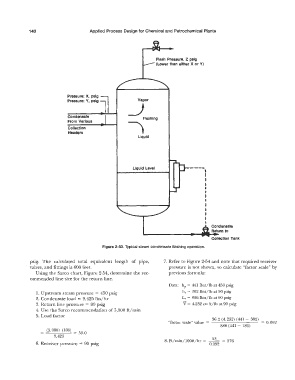

Flash Pressure, Z pslg

(Lower than either X or Y)

Vapor

_)

Condensate Flashing

From Various

Collection l

Headers

Liquid

--

Liquid Level

Condensate

Return to

"'-------------�----4 .. ��

Collection Tank

Figure 2-53. Typical steam condensate flashing operation.

psig. The calculated total equivalent length of pipe, 7. Refer to Figure 2-54 and note that required receiver

valves, and fittings is 600 feet. pressure is not shown, so calculate "factor scale" by

Using the Sarco chart, Figure 2-54, determine the rec- previous formula:

ommended line size for the return line.

Data: hp = 441 Btu/lb at 450 psig

I. Upstream steam pressure = 450 psig hr = 302 Btu/lb at 90 psig

2. Condensate load = 9,425 lbs/hr Lr = 886 Btu/lb at 90 psig

3. Return line pressure = 90 psig V = 4.232 cu ft/lb at 90 psig

4. Use the Sarco recommendation of 5,000 ft/min

5. Load factor

36.2 (4.232) (441 - 302)

"factor scale" value = = 0. 092

886 (441 - 180)

= (5,000) (100) = 53.0

9,425

8. Ft/min/100# /hr = 53 = 576

6. Receiver pressure = 90 psig 0.092