Page 348 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 348

316 Applied Process Design for Chemical and Petrochemical Plants

100

Equal heat transfer 0 • IMPEUER DIAMETER

per unit volume - L,..,,- I/ T•TANK DIAMETER (Co.lSTANT)

I/ v v 20 IMPELLER TYPE CONSTANT----.11�---+-�

1/

v 1,/ time-T 101--��i---�t---+.,..,....-i�- �- �-+--+-1

T• Turbulent flow

- v �qualblend

L• Laminar flow

......

......

10 - - !,, ..... 8t--��+-��-+--7''+---+--+--. ....... �+-.,,,-.�+-�+--+--t

- 61--����.....,C.-+-�+-'1""+-�-.,.c+-��-+-�+--+--t

� ./ ./ (/)

� v (/) 4t--��'4-��-4-. ....... -+---+ ........ ;.._��+-��-+-�-+--+--t

v ... Equal N r, . er equal heat 1ransfer coetficient uJ

(.)

� on i"ti•ivl 'i"['•:.::.+--+-t-tr i

� v v"" - a.

i g ...... ..... - ... - ..--- ........--r II I I I I I I I I

,,/'

.ii ,...-- / - Equal bubble and drop diameter - T

,..-Equal heat transfer coefficient - L

£ 1.0 «'. ... .u

l ' - - ...... � .. Equal mass and heat transfer coefficient: 1...._��"--��.1--......1.�1......J'-----'��--'� ....... ��

Equal blend time

L

'\. ....

l '\. "\. ....... "'- .... - � particles bubbles, drops T QI Q2 0.4 0.6 I 2 4 6 10

I

I I I

I

I

HORSEPOWER

0 I\. -- ..... ......... -,.... "1-N

.2 \ '� Solids suspension - T Figure 5-30. Effect of power on process result with constant D/T

l \ <, . "'±-. ratio. By permission, Fluid Mixing, Lightnin (formerly Mixing Equip-

[\ <, Equal tip speed·- T r--. ........ ment Co.), a unit of General Signal.

0.1

.....

Equal 11p speed - L

\. <, Oitiign test equipment to mo<al proceu

� <,

Equal NR• (land T) ....

11 I\ ......... .... � Operate equrpmanT for r&q�irod prrn:..u ruult

0.01

1 10 100 1,000

Ratio of mixed volumes, V 2 I V 1 or of impeller diameters cubed, (0 1 I 0 1) 1

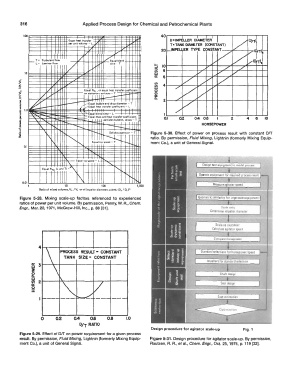

Figure 5-28. Mixing scale-up factors referenced to experienced Geomeiric �imilerity for larfl(! scale equipment

ratios of power per unit volume. By permission, Penny, W. A., Chem.

Engr., Mar. 22, 1971, McGraw-Hill, Inc., p. 88 [31]. S�le ratio

Determine imp�lier drameler

Scwle-up upononr

Calcula1e agitator spee�

Compu!e ho""po,..,,

Standard sstect.nns forhor�power/speed

lmpellerl lor standard ,election

Shalt desrgn

Sear desrgn

Cost estimation

0 Q2 0.4 0.8 0.8 1.0

D/T RATIO

Design procedure for agitator scale-up Fig. 1

Figure 5-29. Effect of Off on power requirement for a given process

result. By permission, Fluid Mixing, Lightnin (formerly Mixing Equip- Figure 5-31. Design procedure for agitator scale-up. By permission,

ment Co.), a unit of General Signal. Rautzen, A. A., et al., Chem. Engr., Oct. 25, 1976, p. 119 [32].