Page 344 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 344

312 Applied Process Design for Chemical and Petrochemical Plants

(Figure 5-23 continued [rom previous page) (text continued [rom page 309)

Vertical Tu be cleaning, and emptying the reactor (see Figures 5-25A

Baffles

and B).

In batch operations, mixing takes place until a desired

composition or concentration of chemical products or

solids/crystals is achieved. For continuous operation, the

feed, intermediate, and exit streams will not necessarily

be of the same composition, but the objective is for the

end/exit stream to be of constant composition as a result

Helical Coil

of the blending, mixing, chemical reaction, solids suspen-

sion, gas dispension, or other operations of the process.

"Perfect" mixing is rarely totally achieved, but represents

the instantaneous conversion of the feed lo the final bulk

and exit composition (see Figure 5-26).

When conducting pilot plant testing to develop a

0

process involving mixing, which later may be used in the

design of a large scale plant, it is wise to discuss the test-

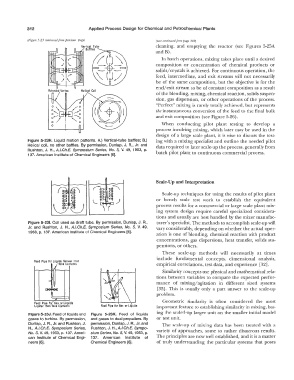

Figure 5-23H. Liquid motion patterns. A.) Vertical-tube baffles; B.) ing with a mixing specialist and outline the needed pilot

Helical coil, no other baffles. By permission, Dunlap, J. R., Jr. and data required to later scale-up the process, generally from

Rushton, J. H., Al-ChE Symposium Series, No. 5, V. 49, 1953, p. batch pilot plant to continuous commercial process.

137. American Institute of Chemical Engineers [6].

Scale-Up and Interpretation

Scale-up techniques for using the results of pilot plant

or bench scale test work lo establish the equivalent

process results for a commercial or large scale plant mix-

ing system design require careful specialized considera-

tions and usually are best handled by the mixer manufac-

Figure 5-231. Coil used as draft tube. By permission, Dunlap, J. R., turer's specialist. The methods to accomplish scale-up will

Jr. and Rushton, J. H., A./.Ch.E. Symposium Series, No. 5, V. 49, vary considerably, depending on whether the actual oper-

1953, p. 137. American Institute of Chemical Engineers [6].

ation is one of blending, chemical reaction with product

concentrations, gas dispersions, heal transfer, solids sus-

pensions, or others.

These scale-up methods will necessarily at times

include fundamental concepts, dimensional analysis,

feed Pipe for Liquids Heavier rnan

Tank Contents empirical correlations, test data, and experience [32].

Similarity concepts use physical and mathematical rela-

tions between variables to compare the expected perfor-

mance of mixing/agitation in different sized systems

[33]. This is usually only a part answer to the scale-up

problem.

Geometric similarity is often considered the most

Feed Pipe for Gas or Liquids

Lighter than Tank Contents feed Pipe for Gas or Li�uids important feature to establishing similarity in mixing, bas-

Figure 5-23J. Feed of liquids and Figure 5-23K. Feed of liquids ing the scaled-up larger unit on the smaller initial model

gases to turbine. By permission, and gases to dual propellers. By or test unit.

Dunlap, J. R., Jr. and Rushton, J. permission, Dunlap, J. R., Jr. and The scale-up of mixing data has been treated with a

H., A.I.Ch.E. Symposium Series, Rushton, J. H., A.I.Ch.E. Sympo- variety of approaches, some to rather disastrous results.

No. 5, V. 49, 1953, p. 137. Ameri- sium Series, No. 5, V. 49, 1953, p.

can Institute of Chemical Engi- 137. American Institute of The principles are now well established, and it is a matter

neers [6]. Chemical Engineers [6]. of truly understanding the particular systems that poses