Page 352 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 352

320 Applied Process Design for Chemical and Petrochemical Plants

cl

bw

z

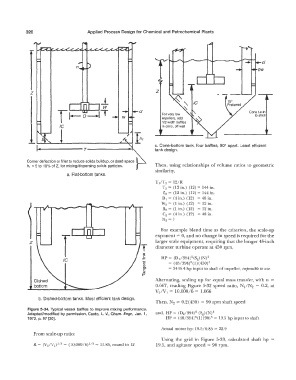

cl Cone tie-in

For very low to shell

impellers, add

1 /2 width baffles

in cone, off wall

c. Cone-bottom tank, four baffles, 90° apart. Least efficient

tank design.

Corner deflection or fillet to reduce solids buildup, or dead space

h 1 = 5 to 10% of Z, for mixing/dispersing solids particles. Then, using relationships of volume ratios to geometric

similarity,

a. Flat-bottom tanks.

T1/T 2 = 12/R

T 2 = (12 in.) (12) = 144 in.

Z2 = (12 in.) (12) = 144 in.

D1 = (4 in.) (12) = 48 in.

W 2 = (1 in.) (12) = 12 in.

B2 = (1 in.) (12) = 12 in.

C2 = (4 in.) (12) = 48 in.

N2 =?

For example blend time as the criterion, the scale-up

exponent= 0, and no change in speed is required for the

z larger scale equipment, requiring that the longer 48-inch

diameter turbine operate at 450 rpm,

Cl)

§ HP = (DT/394)5(Scr) (N)3

c = (48/391) 5 (1)°(450)3

Cl)

Ol = 2445.4 hp input to shaft of impeller, impossible to use.

c

�

Dished Alternating, scaling up for equal mass transfer, with n =

bottom 0.667, reading Figure 5-32 speed ratio, N1/N2 = 0.2, at

V2/V 1 = 10,000/6 = 1,666

b. Dished-bottom tanks. Most efficient tank design.

Then, N2 = 0.2(450) = 90 rpm shaft speed

Figure 5-34. Typical vessel baffles to improve mixing performance.

Adapted/modified by permission, Casto, L. V., Chem. Engr., Jan. 1, and, HP= (0 2 /394)5 (Sg) (N)3

5

3

1972, p. 97 [30]. HP= (48/391) (1)(90) = 19.5 hp input to shaft

Acural motor hp: 19.5/0.85 == 22.9

From scale-up ratio:

Using the grid in Figure 5-33, calculated shaft hp

2

R = (V /V 1)113 = (10,000/6) 113 = 11.85, round to 12 19.5, and agitator speed = 90 rpm.