Page 357 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 357

Mixing of Liquids 325

PRESSURE CONNECTION PRESSURE CONNECTION

DISCHARGE.

Can be

thrHded

or pl1in.

REMOVABLE

NOZZLE

SUCTION

CONNECTION REMOVABLE

THROAT

SUCTION PIECE

REMOVABLE CONNECTION

NOZZLE

SUCTION SUCTIOfl

LIQUID LIQUID

FLOW FLOW

PRESSURE CONNECTION

DISCHARGE DISCHARGE

CONNECTION CONNECTION

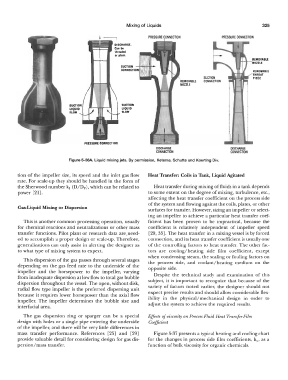

Figure 5-36A. Liquid mixing jets. By permission, Ketema, Schutte and Koerting Div.

tion of the impeller size, its speed and the inlet gas flow Heat Transfer: Coils in Tank, Liquid Agitated

rate. For scale-up they should be handled in the form of

the Sherwood number k 1 (D/Dv), which can be related to Heat transfer during mixing of fluids in a tank depends

power [21]. to some extent on the degree of mixing, turbulence, etc.,

affecting the heat transfer coefficient 011 the process side

of the system and flowing against the coils, plates, or other

Gas-Liquid Mixing or Dispersion surfaces for transfer. However, sizing an impeller or select-

ing an impeller to achieve a particular heat transfer coef-

This is another common processing operation, usually ficient has been proven to be impractical, because the

for chemical reactions and neutralizations or other mass coefficient is relatively independent of impeller speed

transfer functions. Pilot plant or research data are.need- [29, 35]. The heat transfer in a mixing vessel is by forced

ed to accomplish a proper design or scale-up. Therefore, connection, and its heat transfer coefficient is usually one

generalizations can only assist in alerting the designer as of the controlling factors to heat transfer. The other fac-

to what type of mixing system to expect. tors are cooling/heating side film coefficient, except

when condensing steam, the scaling or fouling factors on

This dispersion of the gas passes through several stages the process side, and coolant/heating medium on the

depending on the gas feed rate to the underside of the opposite side.

impeller and the horsepower to the impeller, varying

from inadequate dispersion at low flow to total gas bubble Despite the technical study and examination of this

dispersion throughout the vessel. The open, without disk, subject, it is important to recognize that because of the

radial flow type impeller is the preferred dispersing unit variety of factors noted earlier, the designer should not

because it requires lower horsepower than the axial flow expect precise results and should allow considerable flex-

impeller. The impeller determines the bubble size and ibility in the physical/mechanical design in order to

interfacial area. adjust the system to achieve the required results.

The gas dispersion ring or sparger can be a special Effects of viscosity on Process Fluid Heat Transfer Film

design with holes or a single pipe entering the underside Coefficient

of the impeller, and there will be very little differences in

mass transfer performance. References [25] and [29] Figure 5-37 presents a typical heating and cooling chart

provide valuable detail for considering design for gas dis- for the changes in process side film coefficients, h 0, as a

persion/mass transfer. function of bulk viscosity for organic chemicals.