Page 384 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 384

352 Applied Process Design for Chemical and Petrochemical Plants

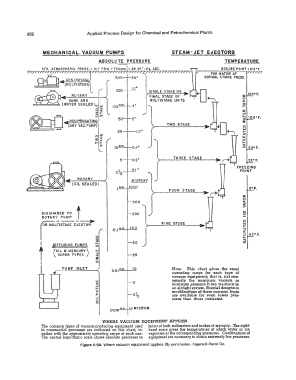

MECHANICAL VACUUM PUMPS STEAM-JET EJECTORS

TEMPERATURE

BOILING POINT= 212°F

FOR WATER AT

NORMAL ATMOS. PRESS.

250 SINGLE STAGE OR

ROTARY Flt.lAL STAGE OF a: 150° F.

,C VANE AND MULTISTAGE UNITS 0

a.

>

(WATER SEALED)w UJ 4" ""

..J <.!)

(!) <I: a:

;z .... l&J

� � I00°F,

RECIPROCATIN: en 50 2" �

� TWO STAGE 0

(DRY VAC.PUMP)

l&J

25 1.0" .....

a:

O UJ ""

�� ::,

........

.....

en

0.4" "" 50° F.

UI

5 0.2"

FREEZING

0.1 11 POINT

ROTARY MICRONS

(OIL SEALED)

1mm. 1000 0°F.

FOUR STAGE

a::

DISCHARGE TO t 500 >

0

a.

""

l&J

. MUL,IST··· .,.� .O .I na, _._"- I O� O FIVE STAGE

ROTARY PUMP 250 o

� 50

i'.!

t DIFFUSION PUMPS z �� 25

1 I

(OIL 6 MERCURY)

-

VAPOR TYPES

in

PUMP INLET O.Oll!!l! �� l � O Note: This chart gives the usual

operating range for each type of

vacuum equipment; that is, not nec-

essarily the maximum vacuum or

5 minimum pressure it can maintain in

an airtight system. Special designs or

modifications of these common types

2� are available for even lower pres-

2

sures than those indicated.

O.OOlmm. =IMICRON

WHERE VACUUM EQUIPMENT APPLIES

The common types of vacuum-producing equipment used terms of both millimeters and inches of mercury. The rlght-

in commercial processes are indicated on this chart, to- hand scale gives the temperatures at which water or ice

gether with the approximate operating range of each 011.e. vaporizes at the corresponding pressures. Combinations of

The central loqarilhmic scale shows absolute pressures in equipment are necessary to obtain extremely low pressures.

Figure 6·9A. Where vacuum equipment applies. By permission, Ingersoll-Rand Co.