Page 385 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 385

Ejectors and Mechanical Vacuum Systems 353

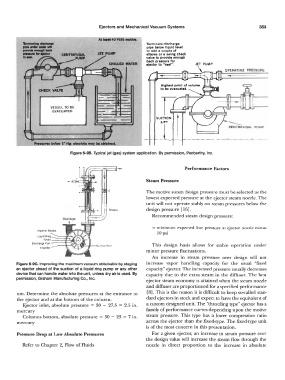

Al I .... 40 PSIG motive.

Terminate discharge

pipe below liquid level

or •dd a couple of

JET PUMP elbows or a swing check

valve to provide enouah

back pressure for

ejector to "seal".

OPERATING PRESSURE

VESSEL TO BE

EVACUATED

SUCTION

LIFT

j

��--�-

PrN_su,.. bet- 1 • H1. 1bsolut1 m11 Ill obt1lnld.

____

Figure 6-98. Typical Jet (gas) system application. By permission, Penberthy, Inc.

Performance Factors

Steam Pressure

The motive steam design pressure must be selected as the

lowest expected pressure at the ejector steam nozzle. The

unit will not operate stably on steam pressures below the

design pressure [16].

Recommended steam design pressure:

= minimum expected line pressure at ejector nozzle minus

10 psi

This design basis allows for stable operation under

minor pressure fluctuations.

An increase in steam pressure over design will not

Figure 6-9C. Improving the maximum vacuum obtainable by staging increase vapor handling capacity for the usual "fixed

an ejector ahead of the suction of a liquid ring pump or any other capacity" ejector. The increased pressure usually decreases

device that can handle water into the unit, unless dry air is used. By capacity due to the extra steam in the diffuser. The best

permission, Graham Manufacturing Co., Inc.

ejector steam economy is attained when the steam nozzle

and diffuser are proportioned for a specified performance

um. Determine the absolute pressures at the entrance to [8]. This is the reason it is difficult to keep so-called stan-

the ejector and at the bottom of the column. dard ejectors in stock and expect to have the equivalent of

Ejector inlet, absolute pressure = 30 - 27.5 = 2.5 in. a custom designed unit. The "throttling type" ejector has a

mercury family of performance curves depending upon the motive

Columns bottom, absolute pressure = 30 - 23 = 7 in. steam pressure. This type has a lower compression ratio

mercury across the ejector than the fixed-type. The fixed-type unit

is of the most concern in this presentation.

Pressure Drop at Low Absolute Pressures For a given ejector, an increase in steam pressure over

the design value will increase the steam flow through the

Refer to Chapter 2, Flow of Fluids nozzle in direct proportion to the increase in absolute