Page 412 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 412

380 Applied Process Design for Chemical and Petrochemical Plants

Absolute Pressure where Pct = piston displacement cu fl/min

Controller

0 V = system volume, cu ft

t = evacuation time, min

Steam P 2 = absolute discharge pressure of pump, psia

Pc = absolute intake pressure of pump with closed intake

P 1 = absolute intake pressure of pump

Process

§�

The relation above is theoretical, and does not take

Discharge into account any inleakage while pumping. It is recom-

mended that a liberal multiplier of perhaps 2 or 3 be used

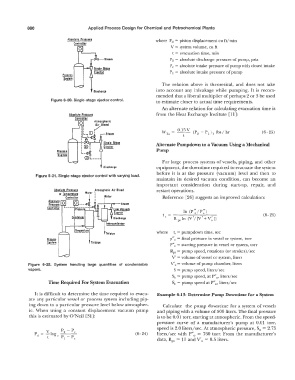

Figure 6-30. Single-stage ejector control. to estimate closer to actual time requirements.

An alternate relation for calculating evacuation time is

from the Heat Exchange Institute [11]:

(6- 25)

Steam

Alternate Pumpdown to a Vacuum Using a Mechanical

Process Pwnp

§_ystem

For large process systems of vessels, piping, and other

Discharge equipment, the downtime required to evacuate the system

before it is at the pressure (vacuum) level and then to

Figure 6-31. Single-stage ejector control with varying load.

maintain its desired vacuum condition, can become an

important consideration during start-up, repair, and

Absolute Pressure 'Atmospheric Air Bleed restart operations.

or Tem�eroture Waler I

Controller I Reference [26] suggests an improved calculation:

Absolute O I

Pressure -- - --'----Steam

Controller �----Pressure-- Low Vacuum

i -

; si� (6- 26)

-,-- Discharge

cJndenser

i

where t, = pumpdown time, sec

0

Process p" = final pressure in vessel or system, torr

§.rstem Toil pipe

P" 0 = starting pressure in vessel or system, torr

Rps= pump speed, rotations (or strokes)/sec

V' = volume of vessel or system, liters

Figure 6-32. System handling large quantities of condensable V' 0 = volume of pump chamber, liters

vapors. S = pump speed, liters/sec

S 0 = pump speed, at P" liters/sec

0,

Time Required For System Evacuation Sn= pump speed at P" liters/sec

0,

It is difficult to determine the time required to evacu- Example 6-13: Determine Pump Downtime for a System

ate any particular vessel or process system including pip-

ing down to a particular pressure level below atmospher- Calculate the pump downtime for a system of vessels

ic. When using a constant displacement vacuum pump and piping with a volume of 500 liters. The final pressure

this is estimated by O'Neil [31]: is to be 0.01 torr, starting at atmospheric. From the speed-

pressure curve of a manufacturer's pump at 0.01 torr,

0

v p - p c speed is 2.0 liters/sec. At atmospheric pressure, S = 2.75

2

Pd= -log (6-24) liters/sec with P" 0 = 760 torr. From the manufacturer's

t c p - p

I c data, Rps = 15 and V' 0 = 0.5 liters.