Page 415 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 415

Ejectors and Mechanical Vacuum Systems 383

STEAM STEAM STEAM STEAM

NASH

SEPARATOR

RECYCLE

TOWER

TOW�R

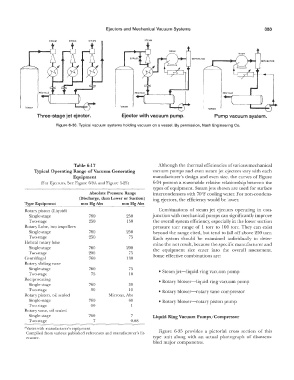

Three-stage jet ejector. Ejector with vacuum pump. Pump vacuum system.

Figuro 6-33. Typical vacuum systems holding vacuum on a vessel. By permission, Nash Engineering Co.

Table 6-17 Although the thermal efficiencies of various mechanical

Typical Operating Range of Vacuum Generating vacuum pumps and even steam jet ejectors vary with each

Equipment manufacturer's design and even size, the curves of Figure

(For Ejectors, See Figure 6-9A and Figure 6-25) 6-34 present a reasonable relative relationship between the

types of equipment. Steam jets shown are used for surface

Absolute Pressure Range intercondensers with 70°F cooling water. For non-condens-

(Discharge, then Lower or Suction) ing ejectors, the efficiency would be lower.

Type Equipment mm Hg Abs mm Hg Abs

--------·---·

Rotary piston (Liquid) Combinations of steam jet ejectors operating in con-

Single-stage 760 250 junction with mechanical pumps can significantly improve

Two-stage 250 150 the overall system efficiency, especially in the lower suction

Rotary Lobe, two impellers pressure torr range of l torr to l.00 torr. They can exist

Single-stage 760 250 beyond the range cited, but tend to fall off above 200 torr.

Two-stage 250 75 Each system should be examined individually to deter-

Helical rotary lobe mine the net result, because the specific manufacturer and

Single-stage 760 200 the equipment size enter into the overall assessment.

Two-st.age 200 75 Some effective combinations are:

Centrifugal 760 130

Rotary sliding vane

Single-stage 760 75 • Steam jet-liquid ring vacuum pump

Two-stage 75 10

Reciprocating • Rotary blower-liquid ring vacuum pump

Single-stage 760 30

Two-st.age 30 10 • Rotary blower-rotary vane compressor

Rotary piston, oil sealed Microns, Abs

Single-stage 760 60 • Rotary blower-rotary piston pump

Two-stage 60

Rotary vane, oil sealed

Single-stage 760 7 Liquid Ring Vacuum Pwnps/Compressor

Two-stage 7 0.08

"Varies with manufacturer's equipment. Figure 6-35 provides a pictorial cross section of this

Compiled from various published references and manufacturer's lit-

erature. type unit along with an actual photograph of disassem-

bled major components.