Page 456 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 456

422 Applied Process Design for Chemical and Petrochemical Plants

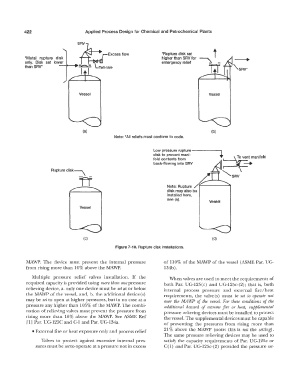

Stb- V

Excess flow *Rupture disk set

*Metal rupture disk higher than SRV for

only. Disk set lower \ - emergency relief

than SRV* --+--•11 \.. Tell-tale

Vessel Vessel

(a) (b)

Note: *All reliefs must conform to code.

Low pressure rupture 1

vent manifold

disk to prevent mani- · � o

fold contents from

back-flowing into SRV -+

A ___

I 1

/__ "-sRV

Note: Rupture /�

disk may also be

installed here,

see (a).

Vessel

Vessel

(c) (d)

Figure 7-10. Rupture disk installations.

MAWP. The device must prevent the internal pressure of 110% of the MAV17P of the vessel (ASME Par. UG-

from rising more than 10% above the l'v!AWP. 134b).

Multiple pressure relief valves installation. If the When valves are used to meet the requirements of

required capacity is provided using more than one pressure both Par. UG-125(c) and UG-125c-(2); that is, both

relieving device, a. only one device must be set at or below internal process pressure and external fire/heat

the MA,VP of the vessel, and, b. the additional device(s) requirements, the valve(s) must be set lo operate not

may be set to open at higher pressures, but in no case at a over the J\tfA HP of the vessel. For these conditions of the

pressure any higher than 105% of the MAV17P. The combi- additional hazard of extreme fire or heat, supplemental

nation of relieving valves must prevent the pressure from pressure relieving devices must be installed to protect

rising more than 16% above the MAWP. See ASME Ref the vessel. The supplemental devices must be capable

[l] Par. UG-125C and C-1 and Par. UG-134a. of preventing the pressures from rising more than

• External fire or heat exposure only and process relief 21 % above the MAWP (note: this is not the setting).

The same pressure relieving devices may be used to

Valves to protect against excessive internal pres- satisfy the capacity requirements of Par. UG-125c or

sures must be set to operate at a pressure not in excess C(l) and Par. UG-125c-(2) provided the pressure set-