Page 457 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 457

Process Safety and Pressure-Relieving Devices 423

• Vessels operating completely filled with liquid must

be equipped with liquid relief valves, unless otherwise

protected (Par. UG-125-3(g).

• Safety and safety relief valves for steam service should

meet the requirements of ASME Par. UG-131 (b), Ref

(1]. Note that the requirements for these valves are

slightly different than for process type valves.

Relieving Capacity of Combinations of Safety Relief Valves and

Rupture Disks or Non-Reclosure Devices (Reference ASME

Code, Par. UG-127, UG-132).

• Primary Relief

A single rupture disk can be used as the only over-

pressure protection on a vessel or system (Figure 7-10).

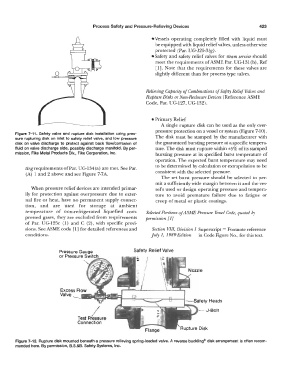

Figure 7-11. Safety valve and rupture disk installation using pres-

sure rupturing disk on inlet to safety relief valve, and low pressure The disk must be stamped by the manufacturer with

disk on valve discharge to protect against back flow/corrosion of the guaranteed bursting pressure at a specific tempera-

fluid on valve discharge side, possibly discharge manifold. By per- ture. The disk must rupture within ±5% of its stamped

mission, Fike Metal Products Div., Fike Corporation, Inc. bursting pressure at its specified burst temperature of

operation. The expected burst temperature may need

ting requirements of Par. UG-134(a) are met. See Par. to be determined by calculation or extrapolation to be

(A) 1 and 2 above and see Figure 7-7A. consistent with the selected pressure.

The set burst pressure should be selected to per-

mit a sufficiently wide margin between it and the ves-

When pressure relief devices are intended primar- sel's used or design operating pressure and tempera-

ily for protection against overpressure due to exter- ture to avoid premature failure due to fatigue or

nal fire or heat, have no permanent supply connec- creep of metal or plastic coatings.

tion, and are used for storage at ambient

temperature of non-refrigerated liquefied com- Selected Portions of ASME Pressure Vessel Code, quoted l1y

pressed gases, they are excluded from requirements permission [I]

of Par. UG-125c (1) and C (2), with specific provi-

sions. See ASME code (1) for detailed references and Section VIII, Division I Superscript = Footnote reference

conditions. July I, /989 Edition in Code Figure No., for this text.

Safety Relief Valve

I ·J-Bolt

Test Pressure

Connection

Figure 7-12. Rupture disk mounted beneath a pressure relieving spring-loaded valve. A reverse buckling® disk arrangement is often recom-

mended here. By permission, B.S.&B. Safety Systems, Inc.