Page 492 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 492

458 Applied Process Design for Chemical and Petrochemical Plants

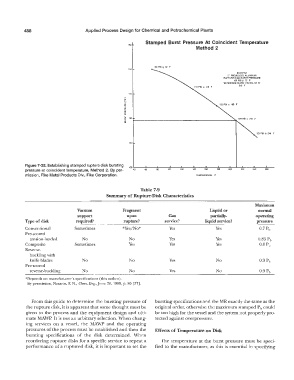

Stamped Burst Pressure At Coincident Temperature

160

Method 2

150 PSI Q1 72 F

150

EXAMPLE

2" PREBULGED ALU,\41NUM

RUPTURE DISC BURST PRESSURE

150 PSI �1 n- F

DETERMINE BURST PRESSURE AT

210 F

"0

130

123 PSI. f1 240 F

120

Figure 7-32. Establishing stamped rupture disk bursting

pressure at coincident temperature, Method 2. By per-

mission, Fike Metal Products Div., Fike Corporation. TEMPERATURE. F

Table 7-9

Summary of Rupture-Disk Characteristics

Maximum

Vacuum Fragment Liquid or normal

support upon Gas partially- operating

Type of disk required? rupture? service? liquid service? pressure

Conventional Sometimes *Yes/No* Yes Yes 0.7 Pb

Pre-scored

tension-loaded No No Yes Yes 0.85 Pb

Composite Sometimes Yes Yes Yes 0.8 Pb

Reverse-

buckling with

knife blades No No Yes No 0.9 Pb

Pre-scored

reverse-buckling No No Yes No 0.9 Pb

*Depends on manufacturer's specifications ( this author).

By permission, Nazario, F. N., Chem. Eng., June 20, l 988, p. 86 [37].

From this guide to determine the bursting pressure of bursting specifications and the MR exactly the same as the

the rupture disk, it is apparent that some thought must be original order, otherwise the maximum stamped Pb could

given to the process and the equipment design and ulti- be too high for the vessel and the system not properly pro-

mate MAWP. It is not an arbitrary selection. When chang- tected against overpressure.

ing services on a vessel, the MAWP and the operating

pressures of the process must be established and then the Effects of Temperature on Disk

bursting specifications of the disk determined. \,Vhen

reordering rupture disks for a specific service lo repeat a The temperature at the burst pressure must be speci-

performance of a ruptured disk, it is important to set the fied to the manufacturer, as this is essential in specifying