Page 571 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 571

Applied Process Design 537

• increasing the surface conductivity through the rais- d = diameter, inches (usually of pipe)

ing of the relative humidity or through surface treat- d' = flare rip diameter, fr

ment D = d, = flare tip diameter, in.

• increasing the conductivity of the air DF = minimum distance from midpoint of flame to

the object, ft

• relative low working speeds dp/dt = rate of pressure rise, bar/sec or psi/sec

• proper choice of contact materials E = joint efficiency in cylindrical or spherical shells

• proper control of the contact temperatures of the or ligaments between openings (see ASME

surfaces Code Par.lJW-12 or UG-53)

e = natural logarithm base, e = 2.718

• or a combination of the above e, = TNT equivalent (explosion) (see Table 7-26)

F = environment factor for Table 7-8

Note that charges can be transported by persons or F'gs = relief valve factor for non-insulated vessels in

containers from a nonhazardous area into an unsuspect- gas service exposed to open fires

ing unsafe ( or hazardous) area and ignition could then F = F h = fraction of heat radiated

]7' = operating environment factor for safety relief of

take place [63]. gas only vessels (see pg. 446)

It is essential that the process hazardous atmosphere F = Flow gas/vapor, cubic feet per minute at 14.7

and the process system and handling of combustible psia and 60°F

hydrocarbons/ chemicals be recognized in the physical Fu = The ratio of the ultimate stress of the vessel to

the allowable stress of the vessel

designs by conforming to the appropriate class of atmos- F, = ratio of the yield stress of the vessel to the allow-

phere/ environment codes specified by the National Elec- able stress of the vessel

trical Code [71, 83, and 84]. F1 or F2 = relief area for vessels 1 or 2 resp., sq ft

F2 = coefficient of subcritical flow (see Figure 7-29)

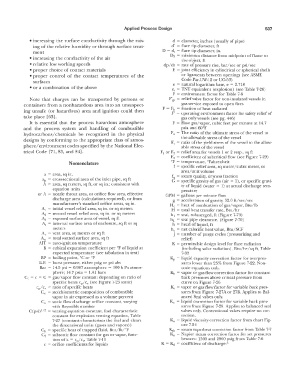

Nomenclature °F = temperature, "Fahrenheit

f = specific relief area, sq meter I cubic meter, or

area/unit volume

a = area, sq in. fq = steam quality, dryness fraction

ap = cross-sectional area of the inlet pipe, sq ft G = specific gravity' of gas (air = 1), or specific gravi-

A = area, sq meters, sq ft, or sq in.; consistent with t:y of liquid (water = I) at actual discharge tem-

equation unit, perature

or A = nozzle throat area, or orifice flow area, effective GPM = gallons per minute flow

discharge area (calculations required), or from g = acceleration of gravity, 32.0 ft/sec/sec

manufacturer's standard orifice areas, sq in. He = heat of combustion of gas/vapor, Btu/lb

A1 = initial vessel relief area, sq in. or sq meters H = total heat transfer rate, Btu/hr

A2 = second vessel relief area, sq in. or sq meters h1 = seal, submerged, ft (Figure 7-70)

A3 = exposed surface area of vessel, sq ft hL = seal pipe clearance, (Figure 7-70)

A. = internal surface area of enclosure, sq ft or sq h = head of liquid, ft

meters he = net calorific heat value, Btu/SCF

Av = vent area, sq meters or sq ft j = number of purge cycles (pressurizing and

A,,, = total wetted surface area, sq ft relief)

1-VT = auto-ignition temperature K = permissible design level for flare radiation

B = cubical expansion coefficient per °F of liquid at (including solar radiation), Btu/hr I sq ft, Table

expected temperature (see tabulation in text) 7-32

0

BP = boiling point, °C or ]7 KP = liquid capacity correction factor for overpres-

B.P. = burst pressure, either psig or psi abs sures lower than 25% from Figure 7-22. Non-

Bar = 14.5 psi= 0.987 atmosphere= 100 k Pa atmos- code equations only.

phere; 14.7 psia = 1.01 bars I<t, = vapor or gas flow correction factor for constant

C1 = c = C = gas/vapor flow constant depending on ratio of back pressures above critical pressure from

specific heats cp/Cv (see Figure 7-25 sonic) curve on Figure 7-26

cp/c,. = ratio of specific heats .K,. = vapor or gas flow factor for variable back pres-

C,, = stoichiometric composition of combustible sures from Figure 7-27A or 27B. Applies to Bal-

vapor in air expressed as a volume percent anced Seal valves only.

C 0 = sonic flow discharge orifice constant, varying Kw = liquid correction factor for variable back pres-

with Reynolds number sures from Figure 7-28. Applies Lo balanced seal

C(psi) 12 = venting equation constant, fuel characteristic valves only. Conventional valves require no cor-

1

constant for explosion venting equation, Table rection.

7-27 (constant characterizes the fuel and clears Ku = liquid viscosity correction factor from chart Fig-

the dimensional units (gases and vapors) ) ure 7-24

Ch = specific heat of trapped fluid, Bm/lb/°F K,1t = steam superheat correction factor from Table 7-7

C2 = subsonic flow constant for gas or vapor, func- K = Napier steam correction factor for set pressures

0

tion of k = c 11/ c., Table 7-11 between 1300 and 2900 psig from Table 7-6

c = orifice coefficients for liquids K = Ker = coefficient of discharge:"