Page 568 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 568

534 Applied Process Design for Chemical and Petrochemical Plants

Lt,a t llt/c

� -.) Ye

I \

:.- \

\

\ R

\

H \

\

\ H

\ Worst

\ � Position

\ _ __.__._.....__

"""---x-�-�

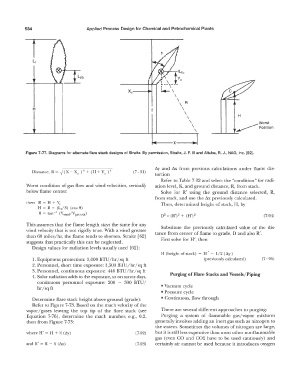

Figure 7-77. Diagrams for alternate flare stack designs of Straitz. By permission, Straitz, J. F. Ill and Altube, R. J., NAO, Inc. [62].

L'iy and Ax from previous calculations under Ilame dis-

Distance, R = � (X- Xe ) + (H + Ye ) 2 (7 - 91)

2

tortion

Refer to Table 7-32 and select the "condition" for radi-

Worst condition of gas flow and wind velocities, vertically ation level, K, and ground distance, R, from stack.

below flame center: Solve for R' using the ground distance selected, R,

from stack, and use the L'ix previously calculated.

then R = H + Ye Then, determined height of stack, H, by

H = R - (Lr/3) (cos 0)

0 = tan - l (V,vind/V gas C,Ul)

02 = (R')2 + (H')2 (7-94)

This assumes that the flame length stays the same for any Substitute the previously calculated value of the dis-

wind velocity that is not rigidly true. With a wind greater tance from center of flame to grade, D and also R'.

than 60 miles/hr, the flame tends to shorten. Straitz [62]

suggests that practically this can be neglected. First solve for H', then

Design values for radiation levels usually used [62]:

H (height of stack) = H' - 1/2 (tiy)

1. Equipment protection: 3,000 BTU/hr/sq ft (previously calculated) (7 - 95)

2. Personnel, short time exposure: 1,500 BTU /hr /sq ft

3. Personnel, continuous exposure: 440 BTU/hr/sq ft

4. Solar radiation adds to the exposure, so on sunny days, Purging of Flare Stacks and Vessels/Piping

continuous personnel exposure: 200 - 300 BTU I

hr/sq ft • Vacuum cycle

• Pressure cycle

Determine flare stack height above ground (grade): • Continuous, flow through

Refer to Figure 7-73. Based on the mach velocity of the

vapor/gases leaving the top tip of the flare stack (see There are several different approaches to purging:

Equation 7-76), determine the mach number, e.g., 0.2, Purging a system of flammable gas/vapor mixtures

then from Figure 7-73: generally involves adding an inert gas such as nitrogen to

the system. Sometimes the volumes of nitrogen are large,

where H' = I-I + J4 (tiy) (7-92) but it is still less expensive than most other nonflammable

gas (even CO and C02 have to be used cautiously) and

and R' = R - � (Ax) (7-93) certainly air cannot be used because it introduces oxygen