Page 41 - E BOOK ENGINE MECHANICAL M2

P. 41

5. SERVICE POINTS OF 4B1 ENGINE COMPONENT

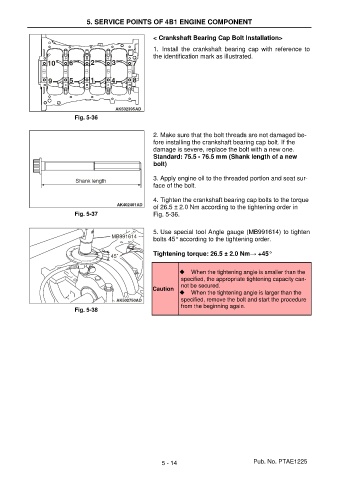

< Crankshaft Bearing Cap Bolt Installation>

1. Install the crankshaft bearing cap with reference to

the identification mark as illustrated.

Fig. 5-36

2. Make sure that the bolt threads are not damaged be-

fore installing the crankshaft bearing cap bolt. If the

damage is severe, replace the bolt with a new one.

Standard: 75.5 - 76.5 mm (Shank length of a new

bolt)

3. Apply engine oil to the threaded portion and seat sur-

face of the bolt.

4. Tighten the crankshaft bearing cap bolts to the torque

of 26.5 ± 2.0 Nm according to the tightening order in

Fig. 5-37 Fig. 5-36.

5. Use special tool Angle gauge (MB991614) to tighten

bolts 45° according to the tightening order.

Tightening torque: 26.5 ± 2.0 Nm→ +45°

◆ When the tightening angle is smaller than the

specified, the appropriate tightening capacity can-

not be secured.

Caution

◆ When the tightening angle is larger than the

specified, remove the bolt and start the procedure

from the beginning again.

Fig. 5-38

5 - 14 Pub. No. PTAE1225