Page 37 - E BOOK ENGINE MECHANICAL M2

P. 37

5. SERVICE POINTS OF 4B1 ENGINE COMPONENT

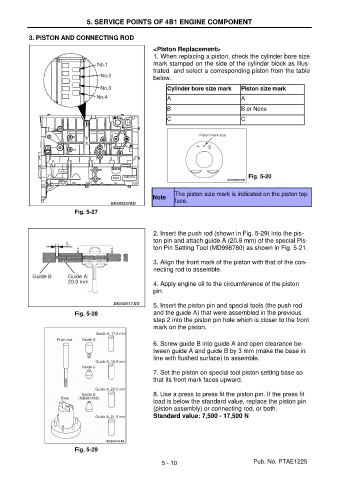

3. PISTON AND CONNECTING ROD

<Piston Replacement>

1. When replacing a piston, check the cylinder bore size

mark stamped on the side of the cylinder block as illus-

trated and select a corresponding piston from the table

below.

Cylinder bore size mark Piston size mark

A A

B B or None

C C

Fig. 5-20

The piston size mark is indicated on the piston top

Note

face.

Fig. 5-27

2. Insert the push rod (shown in Fig. 5-29) into the pis-

ton pin and attach guide A (20.9 mm) of the special Pis-

ton Pin Setting Tool (MD998780) as shown in Fig. 5-21.

3. Align the front mark of the piston with that of the con-

necting rod to assemble.

4. Apply engine oil to the circumference of the piston

pin.

5. Insert the piston pin and special tools (the push rod

Fig. 5-28 and the guide A) that were assembled in the previous

step 2 into the piston pin hole which is closer to the front

mark on the piston.

6. Screw guide B into guide A and open clearance be-

tween guide A and guide B by 3 mm (make the base in

line with flushed surface) to assemble.

7. Set the piston on special tool piston setting base so

that its front mark faces upward.

8. Use a press to press fit the piston pin. If the press fit

load is below the standard value, replace the piston pin

(piston assembly) or connecting rod, or both.

Standard value: 7,500 - 17,500 N

Fig. 5-29

5 - 10 Pub. No. PTAE1225