Page 38 - E BOOK ENGINE MECHANICAL M2

P. 38

5. SERVICE POINTS OF 4B1 ENGINE COMPONENT

<Connecting Rod Bearing Installation>

1. When replacing a connecting rod bearing, select the

bearing corresponding to the crankshaft pin outside di-

ameter according to the crankshaft pin identification in

the table below.

Crankshaft pin Connecting rod bearing

Identification Journal di- Identification Identification

mark ameter mm color mark

1 47.966 - Black 1

47.972

2 47.960 - None or pur- 2

47.966 ple

3 47.954 - Green 3

47.960

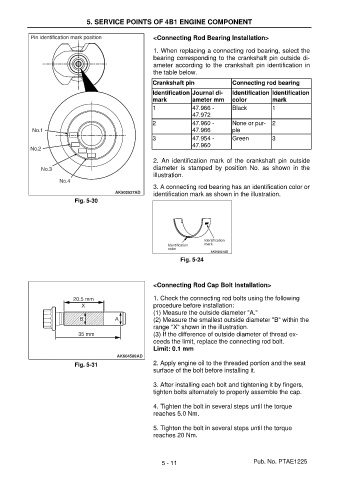

2. An identification mark of the crankshaft pin outside

diameter is stamped by position No. as shown in the

illustration.

3. A connecting rod bearing has an identification color or

identification mark as shown in the illustration.

Fig. 5-30

Fig. 5-24

<Connecting Rod Cap Bolt Installation>

1. Check the connecting rod bolts using the following

procedure before installation:

(1) Measure the outside diameter "A."

(2) Measure the smallest outside diameter "B" within the

range "X" shown in the illustration.

(3) If the difference of outside diameter of thread ex-

ceeds the limit, replace the connecting rod bolt.

Limit: 0.1 mm

Fig. 5-31 2. Apply engine oil to the threaded portion and the seat

surface of the bolt before installing it.

3. After installing each bolt and tightening it by fingers,

tighten bolts alternately to properly assemble the cap.

4. Tighten the bolt in several steps until the torque

reaches 5.0 Nm.

5. Tighten the bolt in several steps until the torque

reaches 20 Nm.

5 - 11 Pub. No. PTAE1225