Page 646 - CarrLaneCatalog_2019ed-c.pdf

P. 646

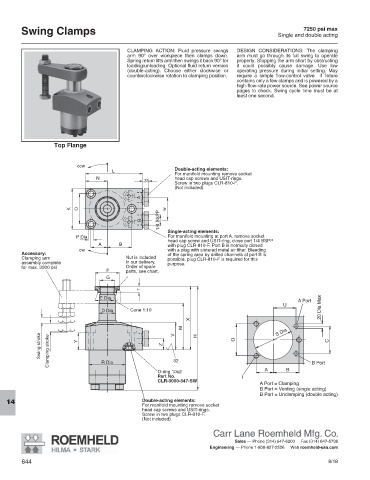

Swing Clamps 7250 psi max

Single and double acting

CLAMPING ACTION: Fluid pressure swings DESIGN CONSIDERATIONS: The clamping

arm 90° over workpiece then clamps down. arm must go through its full swing to operate

Spring return lifts arm then swings it back 90° for properly. Stopping the arm short by obstructing

loading/unloading. Optional fluid return version it could possibly cause damage. Use low

(double-acting). Choose either clockwise or operating pressure during initial setting. May

counterclockwise rotation to clamping position. require a simple flow-control valve if fixture

contains only a few clamps and is powered by a

high-flow-rate power source. See power source

pages to check. Swing cycle time must be at

least one second.

Top Flange

ccw

L Double-acting elements:

For manifold mounting remove socket

N head cap screws and USIT-rings.

.31

Screw in two plugs CLR-810-F.

(Not included).

A

K O w

B 1/4 BSPP

Single-acting elements:

P Dia For manifold mounting at port A, remove socket

head cap screw and USIT-ring, close port 1/4 BSPP

A B with plug CLR-810-F. Port B is normally closed

cw with a plug with sintered metal air filter. Bleeding

Accessory: of the spring area by drilled channels at port B is

Clamping arm Nut is included possible, plug CLR-810-F is required for this

assembly complete in our delivery. purpose.

for max. 3000 psi Order of spare

F parts, see chart.

G

T

E Dia

D Dia Cone 1:10

X

M H

Swing stroke Clamping stroke Y Z

V

32

R Dia

O-ring 10x2

Part No.

CLR-3000-347-SW

Double-acting elements:

For manifold mounting remove socket

14

head cap screws and USIT-rings.

Screw in two plugs CLR-810-F.

(Not included).

Carr Lane Roemheld Mfg. Co.

Sales — Phone (314) 647-6200 Fax (314) 647-5736

Engineering — Phone 1-800-827-2526 Web roemheld-usa.com

644 8/18