Page 28 - MODULE QUALITY TOOLS DMQ 30262

P. 28

DMQ 30262

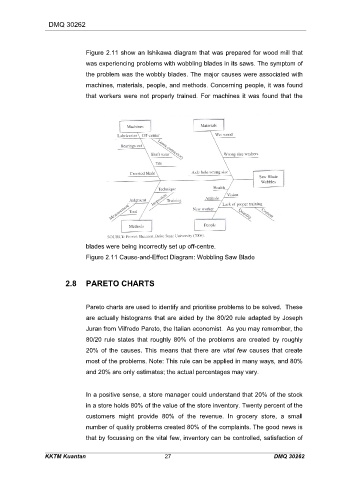

Figure 2.11 show an Ishikawa diagram that was prepared for wood mill that

was experiencing problems with wobbling blades in its saws. The symptom of

the problem was the wobbly blades. The major causes were associated with

machines, materials, people, and methods. Concerning people, it was found

that workers were not properly trained. For machines it was found that the

blades were being incorrectly set up off-centre.

Figure 2.11 Cause-and-Effect Diagram: Wobbling Saw Blade

2.8 PARETO CHARTS

Pareto charts are used to identify and prioritise problems to be solved. These

are actually histograms that are aided by the 80/20 rule adapted by Joseph

Juran from Vilfredo Pareto, the Italian economist. As you may remember, the

80/20 rule states that roughly 80% of the problems are created by roughly

20% of the causes. This means that there are vital few causes that create

most of the problems. Note: This rule can be applied in many ways, and 80%

and 20% are only estimates; the actual percentages may vary.

In a positive sense, a store manager could understand that 20% of the stock

in a store holds 80% of the value of the store inventory. Twenty percent of the

customers might provide 80% of the revenue. In grocery store, a small

number of quality problems created 80% of the complaints. The good news is

that by focussing on the vital few, inventory can be controlled, satisfaction of

KKTM Kuantan 27 DMQ 30262