Page 29 - MODULE QUALITY TOOLS DMQ 30262

P. 29

DMQ 30262

the most important customers can be increased, 80% of the complaints can

be eliminated.

There are some rules for constructing Pareto charts:

Information must be selected based on types or classifications of defects

that occur as a result of a process. An example of this might be the

different types of defects that occur in a semiconductor.

Data must be collected and classified into categories.

A histogram or frequency chart is constructed showing the number of

occurrences.

The steps used in Pareto analysis include:

a. Gathering categorical data relating to quality problems.

b. Drawing a histogram of the data.

c. Focusing on the tallest bars in the histogram first when solving the

problem.

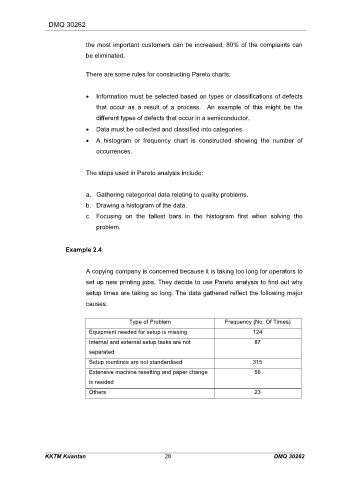

Example 2.4:

A copying company is concerned because it is taking too long for operators to

set up new printing jobs. They decide to use Pareto analysis to find out why

setup times are taking so long. The data gathered reflect the following major

causes:

Type of Problem Frequency (No. Of Times)

Equipment needed for setup is missing 124

Internal and external setup tasks are not 87

separated

Setup rountines are not standardised 315

Extensive machine resetting and paper change 56

is needed

Others 23

KKTM Kuantan 28 DMQ 30262