Page 104 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 104

88 Applied Process Design for Chemical and Petrochemical Plants

k e

0 20 40 60 80

20 Le

5,000-:

I 4POO "° d

;;L ,- 3POO�

,- 60-

:: t: ,-

� 2,000 i 50-:

...

=

�

Globe valve,open } 10 ..._' -: 40-::

9 c:,, l,OOOi �

.... '

8 ...... 800 � 30�

--

....

Cl

7 � 5 - -

8

680-

6 .,. 40 :;; 20 -,_ 24

c:,

�; 300{ _,_ 20

5 18

-

.

-

-

Angle valve, open }-- -"" �I 200 : _,_ 16

I

c:

"Ball check valve, open -� a 1 - -f- rn

Swing check valve, open ;;; = a,

c:

•45°-Y Globe valve, open <..> 100-= ·= to-- 10 c:

-

0

I 00°close screwed return 60� - 8 -

so'.§

.i:::.

� - .E 8-- -�

...

..

...

6 -

...

-

Screwed or fabricated tee 50- 0 'O 7�

),:

thru bronch ond }� 40i __. - 6 "O

90°single-miter elbow iii s�- 5 �

30-: .i:::. ..

..

...

a,

...

Welding tee lhru branch }---._ 20: c 'O 4-- 4 .�

-

.,

}

•sutterfly valve, open <, . - � 3 'tz

...

Submerged discharge \ I - c "' 3-- 3 -�

c

=

•3-Way plua cock, st. thru, open � : I 10..; ·- -=- 21/z a..

-

a

90 standard screwed or }--:-L � � 8� .� a -

D

60° single-miter elbow 0.:, - . 6-:: O' u 2-:- 2 ·e

::,

c:

- ::,

--

-

--

0

45"1olerol thru branch } 0.8 a,/ . 5- "' - l�z z

0.7-

-

90" long-sweep or }� 0 ' " A - 11/4

-

,•

90°double - miler elbow � \

=

-

•p1ug cock, full port, open o, �} \ \ / -;: '.;-

\

Screwed or fobricoled :..1?.-........ ..... \I\/,,- o.s-=- 314

tee or lateral thru run } o4 '� 0.1.::

submerged entrance 3- - 0.8-c: 0.6-= ,_. h

I

-

o.s-

90° triple- miler or 04 �] ; .. - "' 0.6-::

4 5°single miler elbow �� � Enlorging } Sudden·

x

180°welding return or � ;;. - Contracting chcnqe

rn section

4 5° screwed el bow 11 -o u I\ . rSA

-- -�

,....___

Welding tee thru run � \ ' Enlarg,n� reducer

Contract mg ( ta 12" size)

90" welding elbow } '

45°welding elbow or } •' Note: d = Small Pipe I dio. inc hes

\\

gate valve, open 0.1

0.09 d'= Lorge Pipe, dia. inc hes

0.08 - R = Bend Radius I inc he

0.07 "" For Eccentric Reducers I ncentric

Increase Values of Co

0.06 \, 'Enlarging } R�ducer O . Reducers by 33 1/3 o Yo.

20

\'

Contracting �,th

' ,.:.i, included ang re Values for Tees and Lal era ls

0.05 ,r \' Apply lo Full Size Fift

'\. l ings,

0.04 Losses Larger for Side Oullels.

" •Added by author 1-7 6

'

0.03 \ 3-Way plug cock op ening Is

80% of pipe size.

For partially closed globe-type valves,

For elbows 8 bends: R/d; 0 2 4 6 8

For confroctions 8r , Multiply open L 9 by:

enlargements: did: O 0.2 0.4 0.6 0.8 3/4 open 3.25

1/2open 12.0

1 /4 open 72.0

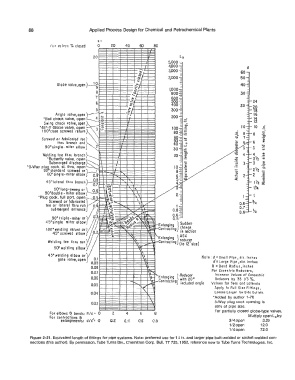

Figure 2-21. Equivalent length of fittings for pipe systems. Note: preferred use for 1 � in. and larger pipe butt-welded or socket-welded con-

nections (this author). By pennission, Tube Turns Div., Chemitron Corp. Bull. TI 725, 1952, reference now to Tube Turns Technologies, Inc.