Page 201 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 201

172 Applied Process Design for Chemical and Petrochemical Plants

The "single" mechanical seal is made of a rotating ele- used under various conditions 111 the wide variety of

ment fixed to the shaft (or shaft sleeve), and a stationary process fluids.

element fixed to the pump casing [16]. The average unbalanced external seal is good for pres-

The "double" seal is for severe sealing problems where sures of about 30 psig, while the balanced design will han-

out-leakage to the environment cannot be tolerated and dle 150 psig. Special designs will handle much higher

must be controlled. (See Figures 3-31C and 3-310.)

Depending upon the fluid's characteristics, the vent

Flush

between the double seals (Figures 3-31A and B) may be Gland connection

gas�et

purged with process liquid, or a different liquid or oil, or

it may be connected to a seal pot and vent collection to Drive pi,n Gland

prevent leakage to the air/ environment. There are tech- Stuffing-box $ring

housing ',,

niques for testing for leakage of the inner seal by measur- '

ing the vent space pressure through the seal liquid surge '

port. This should be essentially atmospheric (depending

on the vent system backpressure). This allows detection

before the leakage breaks through the outer seal.

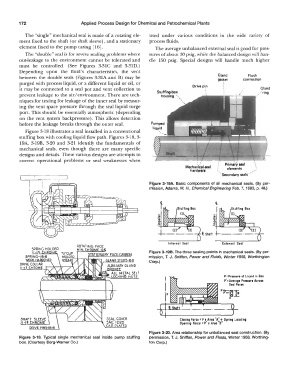

Figure 3-18 illustrates a seal installed in a conventional

stuffing box with cooling liquid flow path. Figures 3-18, 3-

l9A, 3-198, 3-20 and 3-21 identify the fundamentals of

mechanical seals, even though there are many specific

designs and details. These various designs are attempts to

correct operational problems or seal weaknesses when

I I Primary seal '.

'I

Mechanical-seal , elements )

hardware

-. Secondary seals_,�

e,-� : -- . - =-_]

I Ir;;'. , ��� Figure 3-19A. Basic components of all mechanical seals. (By per-

I mission, Adams, W. H., Chemical Engineering Feb. 7, 1983, p. 48.)

· (3) (2)

't Shafi+-·--·--·-·

Internal Seal Exltrnol Seol

SPRING HOLDER

U:H HR M Figure 3-198. The three sealing points in mechanical seals. (By per-

SPRING-18·8 mission, T. J. Sniffen, Power and Fluids, Winter 1958, Worthington

WORK HAR ENED Corp.)

DRIVE COLI AR

L'.:.!.� CHROME.

P: Prtnurt of Liquid in Boa

p':Avtrage Pressure Across

Stol Facts

Closi�g Foret: P 1 1 Arta "A:: t, Spring Loading

Opening Force : P I Arto B

Figure 3-20. Area relationship for unbalanced seal construction. (By

Figure 3-18. Typical single mechanical seal inside pump stuffing permission, T. J. Sniffen, Power and Fluids, Winter 1958, Worthing-

box. (Courtesy Borg-Warner Co.) ton Corp.)