Page 202 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 202

Pumping of Liquids 173

P = Pressure of Liquid in 801 all mechanical seals) and must not attack the material of

p': Averogt Prtnure Across

Stol Focn the 0-ring shaft packing. Many other designs are avail-

able, and the manufacturers should be consulted for

advice on specific sealing problems.

Centrifugal Pump Selection

The centrifugal pump is a versatile unit in the process

Closing Force = P � (Areo " � :- � rea"c") + Spring Loading

Oeening Force : P I Area B plant, since its ease of control, non-pulsing flow, pressure

'l\ ,"e" and "c" ore Vorloblt

limiting operation fits many small and large flow systems.

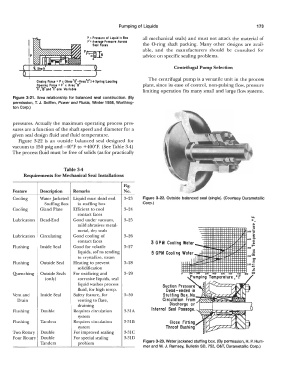

Figure 3-21. Area relationship for balanced seal construction. (By

permission, T. J. Sniffen, Power and Fluids, Winter 1958, Worthing-

ton Corp.)

pressures. Actually the maximum operating process pres-

sures are a function of the shaft speed and diameter for a

given seal design fluid and fluid temperature.

Figure 3-22 is an outside balanced seal designed for

vacuum to 150 psig and -40°F to +400°F. (See Table 3-4)

The process fluid must be free of solids (as for practically

Table 3-4

Requirements for Mechanical Seal Installations

Fig.

Feature Description Remarks No.

Cooling Water Jacketed Liquid must dead end 3-23 Figure 3-22. Outside balanced seal (single). (Courtesy Durametallic

Stuffing Box in stuffing box Corp.)

Cooling Gland Plate Efficient to cool 3-24

contact faces

Lubrication Dead-End Good under vacuum, 3-25 0

....

11>

mild abrasives metal- -

:::,

metal, dry seals >000

...

....

Lubrication Circulating Good cooling of 3-26 400 e

contact faces 3 GPM Cooling Wafer_ Cb

Flushing Inside Seal Good for volatile 3-27 3001-

liquids, sol'ns tending 5 GPM Cooling Wafer >C

0

to crystallize, steam 200CD

DI

c:

-

,

Flushing Outside Seal Heating to prevent 3-28 I II II , 100=

solidification �

Quenching Outside Seals For oxidizing and 3-29 0 100 • 2 300 400 soo 600 700 • oo en

(only) corrosive liquids, seal

liquid washes process

fluid, for high temp.

Vent and Inside Seal Safety feature, for 3-30

Drain venting to flare,

draining

Flushing Double Requires circulation 3-31A

system

Flushing Tandem Requires circulation 3-31B

system

Two Rotary Double For improved sealing 3-31C

Four Rotary Double For special sealing 3-310

Tandem problem Figure 3-23. Water jacketed stuffing box. (By permission, H. P. Hum-

mer and W. J. Ramsey, Bulletin SD, 752, O&T, Durametallic Corp.)