Page 277 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 277

Mechanical Separations 247

s r r r r r 1 r r r

4

3

2

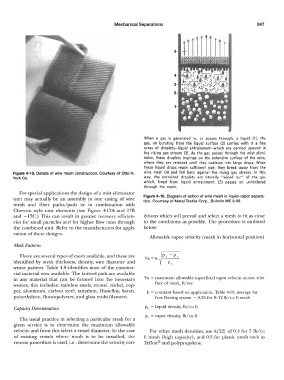

When a gas is generated in, or passes through, a liquid (1), the

gas, on bursting from the liquid surface (2) carries with it a fine

spray of droplets-liquid entrainment-which are carried upward in

the rising gas stream (3). As the gas passes through the mist elimi-

nator, these droplets impinge on the extensive surface of the wire,

where they are retained until they coalesce into large drops. When

these liquid drops reach sufficient size, they break away from the

Figure 4-15. Details of wire mesh construction. Courtesy of Otto H. wire mesh (4) and fall back against the rising gas stream. In this

York Co. way, the entrained droplets are literally "wiped out" of the gas

which, freed from liquid entrainment, (5) passes on unhindered

through the mesh.

For special applications the design of a mist eliminator

unit may actually be an assembly in one casing of wire Figure 4-16. Diagram of action of wire mesh in liquid-vapor separa-

tion. Courtesy of Metal Textile Corp., Bulletin ME 9-58.

mesh and fiber packs/pads or in combination with

Chevron style mist elements (see Figure 4-l 7A and 17B

and -17C.) This can result in greater recovery efficien- ditions which will prevail and select a mesh to fit as close

cies for small particles and for higher flow rates through to the conditions as possible. The procedure is outlined

the combined unit. Refer to the manufacturers for appli- below:

cation of these designs.

Allowable vapor velocity (mesh in horizontal position)

Mesh Patterns

There are several t)'pes of mesh available, and these are

identified by mesh thickness, density, wire diameter and

weave pattern. Table 4-9 identifies most of the commer-

cial material now available. The knitted pads are available

in any material that can be formed into the necessary Va = maximum allowable superficial vapor velocity across inlet

weaves, this includes: stainless steels, monel, nickel, cop- face of mesh, fl/sec

per, aluminum, carbon steel, tantalum, Hastelloy, Saran, k = constant based on application, Table 4-10, average for

polyethylene, fluoropolymer, and glass multi-filament. free flowing system = 0.35 for 9-12 lb/cu ft mesh

Capacity Determination PL = liquid density, lb/ cu fl

p, = vapor density, lb/ cu ft

The usual practice in selecting a particular mesh for a

given service is to determine the maximum allowable

velocity and from this select a vessel diameter. In the case For other mesh densities, use k(52) of 0.4 for 5 lb/cu

of existing vessels where mesh is to be installed, the ft mesh (high capacity), and 0.3 for plastic mesh such as

reverse procedure is used, i.e., determine the velocity con- Teflon® and polypropylene.