Page 278 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 278

248 Applied Process Design for Chemical and Petrochemical Plants

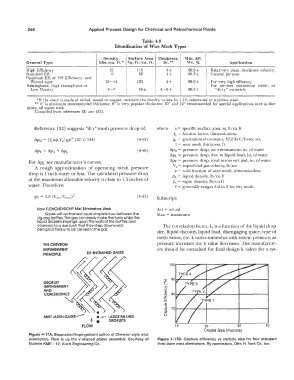

Table 4-9

Identification of Wire Mesh Types

I

Density, Surface Area Thickness, Min. Eff.

General Type Lbs./cu. ft.* Sq. ft./cu. ft. In.** Wt.% Application

High Efficiency 12 115 4+ 99.9+ Relatively clean, moderate velocity.

Standard Eff. ll 85 4+ 99.5+ General purpose

Optimum Eff. or VH Efficiency. and

Wound type 13-14 120 4+ 99.9+ For very high efficency

Herringbone, High through-put or For services containing- solids, or

Low Density 5--7 65± 4-6+ 99.0+ "dirty" materials

I

-

"If the mesh is made of nickel, monel or copper, multiply the density values by 1.13, referenced to stainless steel.

•• 4" is minimum recommended thickness; 6" is very popular thickness; IO" and 12" recommended for special applications such as fine

mists, oil vapor mist.

Compiled from references (3) and (21).

Reference [52] suggests "dry" mesh pressure drop of: where a = specific surface area, sq ft/ cu ft

( = friction factor, dimensionless

(4-45) gc = gra\'itational constant, 32.2 lb-ft/lb-sec-sec

1 = wire mesh thickness, ft

(4-46) Ll.pn = pressure drop, no entrainment, in. of water

Ll.p'L = pressure drop, due to liquid load, in. of water

For �PL see manufacturer's curves. Ll.f>r = pressure drop, total across wet pad, in. of water

A rough approximation of operating mesh pressure V, = superficial gas velocity, ft/sec

drop is 1 inch water or less. The calculated pressure drop E = void fraction of wire mesh, dimensionless

at the maximum allowable velocity is close to 1.5 inches of PL= liquid density, lb/cu ft

p, = vapor density, lb/ cu ft

water. Therefore: f = generally ranges 0.2 to 2 fur dry mesh

(4-47) Subscript:

How FLEXICHEVRON® Mist Eliminators Work Act = actual

Gases with entrained liquid droplets flow between the Max = maximum

zig-zag baffles. The gos can easily make the turns while the

liquid droplets impinge upon the walls of the baffles and

coalesce to a size such that they drop downward, The correlation factor, k, is a function of the liquid drop

being too heavy to be carried in the gas.

size, liquid viscosity, liquid load, disengaging space, type of

mesh weave, etc. k varies somewhat with system pressure; as

THE CHEVRON pressure increases the k value decreases. The manufactur-

IMPINGEMENT ers should be consulted for final design k valves for a sys-

PRINCIPLE DE-ENTRAINED GASES

MIST LADEN GASES-- .i e - LARGE FALLING

T e DROPLETS

FLOW 10 20 30 40

Droplet Size (microns)

Figure 4-17A. Separation/Impingement action of Chevron-style mist

eliminators. Flow is up the V-shaped plates assembly. Courtesy of Figure 4-178. Capture efficiency vs particle size for four standard

Bulletin KME - 12, Koch Engineering Co. York-Vane mist eliminators. By permission, Otto H. York Co. Inc.