Page 340 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 340

308 Applied Process Design for Chemical and Petrochemical Plants

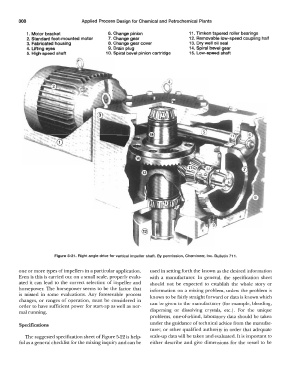

1 . Motor bracket 6. Change pinion 11. Timken tapered roller bearings

2. Standard foot-mounted motor 7. Change gear 12. Removable low-speed coupling half

3. Fabricated housing 8. Change gear cover 13. Dry well oil seal

4. Lifting eyes 9. Drain plug 14. Spiral bevel gear

5. High- speed shaft 1 O. Spiral bevel pinion cartridge 15. Low-speed shaft

Figure 5-21. Right angle drive for vertical impeller shaft. By permission, Chemineer, Inc. Bulletin 711.

one or more types of impellers in a particular application. used in setting forth the known as the desired information

Even is this is carried out on a small scale, properly evalu- with a manufacturer. In general, the specification sheet

ated it can lead to the correct selection of impeller and should not be expected to establish the whole story or

horsepower. The horsepower seems to be the factor that information on a mixing problem, unless the problem is

is missed in some evaluations. Any foreseeable process known to be fairly straight forward or data is known which

changes, or ranges of operation, must be considered in

order to have sufficient power for start-up as well as nor- can be given to the manufacturer (for example, blending,

mal running. dispersing or dissolving crystals, etc.). For the unique

problems, one-of-a-kind, laboratory data should be taken

under the guidance of technical advice from the manufac-

Specifications

turer, or other qualified authority in order that adequate

The suggested specification sheet of Figure 5-22 is help- scale-up data will be taken and evaluated. It is important to

ful as a general checklist for the mixing inquiry and can be either describe and give dimensions for the vessel to be