Page 342 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 342

310 Applied Process Design for Chemical and Petrochemical Plants

SPEC. DWG. NO.

A-

-·

Job No.

Page of Pages

Unit Price

B/M No.

No .Units

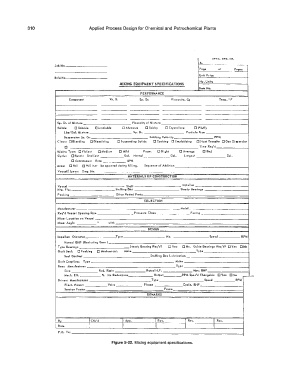

MIXING EQUIPMENT SPECIFICATIONS

Item No.

PERFORMANCE

Component Wt.% Sp, Gr. Viscosity, Cp Temp.° F

Sp. Gr .. of Mixture Viscosity of Mixture

Solids: CJ Soluble CJ Insoluble D Abrasive CJ Sticky [J Crystal I ine CJ Fluffy

Lbs/Gol. Mixture Sp. Gr. Particle Size

Suspension Sp. Gr. Sett) ing Velocity FPM

Class: [J Blending CJ Di ssol'w'ing D Suspending Selids. CJ Cooking D Emulsifying D Heat Transfer D Gos Dispersion

1

CJ Time Req d

Mixing Type: CJ Violent [J Medium CJ Mild Foam: CJ Slight CJ A v eroge CJ Bod

Cycle: CJ Botch: Smallest Gal. Normal Gal. Large,t Gol.

D Continuou5: Rate GPM

Mixer [JWIII [JWill Not be operated during filling. Sequence of Addition

Vessell Spe�s: Dwg. No,

... MATERIALS OF CONSTRUCTION

Impeller

Vessel Shaft

Mtg. Fig. Stuffing Bax Steady Bearings

Packing Other Wetted Parts

-

SELECTION

Monufocturer Model

Roq'd Vessel Opening Size Pressure Class Facing

Ml,cer Location on Vessel

Mixer Angle 0 with

DESIGN

Impeller: Diameter Type No. Speed RPM

Normal BHP (Excluding Geor)

Type Bearings Sfeady Bearing Req'd? [J Yes CJ No. Guide Bearings Req'd? DY•• DNo

Shalt Seal: CJ Packing D Mechanical. Make Type

Seal Coolant Stuffing Box Lubrication

Shalt Coupling: Type Make

Geor: Manufacturer Type

She Reel. Ratio Rated H.P. Mox. BHP

Mech. Ell. %. No Reductions Output RPM Spec'd Chongoble CJ Yes CJ No --

Driver: Manufacturer Type Speed RPM

Elect. Power: Volts P hose Cycle. BHP

Service Factor Fromc

REMARKS

By lchk'd I App. I Rev. I Rev. I Rev.

Date I I I I I

P.O. To:

Figure 5-22. Mixing equipment specifications.