Page 387 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 387

Ejectors and Mechanical Vacuum Systems 355

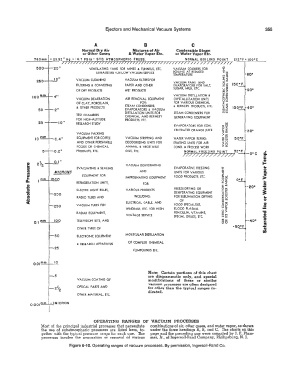

A B c

Normal Dry Air Mixtures of Air Condensible Steam

or Other Gases & Water Vapor Etc. or Water Vapor Etc.

760mm , 29.92" Hg.• 14.7 PSJA- STD. ATMOSPHERIC PRESS. NORMAL BOILING POINT 212•F• ioc-c

T/77777777777777777777777777777777777777777777777777777777

500 -20" VENTILATING FANS FOR MINES & TUNNELS, ETC. VACUUM COOKERS FOR c 0

z

EXHAUSTERS FOR LOW VACUUM SERVICE BOILING AT REDUCED < .... f • ·

TEMPERATURE C) �

10" VACUUM CLEANING VACUUM FILTERS FOR �<

250 VACUUM PANS AND -""

ALTERING & CONVEYING PAPER AND OTHER EVAPORATORS FOR SAL:, 5 C) 1501

caz

u ln

OF DRY PRODUCTS WET PRODUCTS SUGAR, MILK, ETC. ...... 60°

ii:Z

IOOmm 4" VACUUM DISTILLATION & :i:c

a..Z

VACUUM DEAERATION AIR REMOVAL EQUIPMENT CRYSTALLIZATION UNITS "'O

Ov

OF CLAY, PORCELAIN, FOR: FOR VARIOUS CHEMICAL � :I

& OTHER PRODUCTS STEAM CONDENSERS, & REFINERY PRODUCTS, ETC. <{ <

ca..,

50 2" EVAPORATORS & VACUUM ::,,- 100,40'

DISTILLATION UNITS FOR STEAM CONDENSERS FOR V>V>

TEST CHAMBERS CHEMICAL AND REFINERY GENERA TING EQUIPMENT

FOR HIGH-ALTITUDE PRODUCTS, ETC.

25 --1.0" RESEARCH STUDY ....

EVAPORATORS FOR CON- "'C)

oz

CENTRA TED ORANGE JUICE c..< 20°

<{a:

VACUUM PACKING >o:

10 mm 0.4" EQUIPMENT FOR COFFEE VACUUM STRIPPING AND II' ATER VAPOR REFRIG, "'� 50 �

... V>

AND OTHER PERISHABLE DEODORIZING UNITS FOR ERA TING UNITS FOR AIR '""O

<{ 0

FOODS OR CHEMICAL ANIMAL & VEGETABLE COND. & PROCESS WORK 3: ca

5-t-0,2" PRODUCTS, ETC. OILS, ETC. NORMAL FREEZING POINT 32°F. o•c ,:i

/7/777/77777777 E

0.1"

G> 2't. �

I,, 2 EVACUATING & SEALING VACUUM DEHYDRATING EVAPORATIVE FREEZING .... I,,

= en MICRONS AND UNITS FOR VARIOUS z 0

....

en

1:1.

:I

_...,

e EOUIPMENT FOR, IMPREGNATING EQUIPMENT FOOD PRODUCTS, ETC. ::>I!) >

c;

c.. •

A. 1mm 1000 REFRIGERATION UNITS, Oz o•F. I,,

... FOR FREEZE-DRYING OR z « -20· .!!

""<

G>

=

Oo:

C'CI

0 -500 ELECTRIC LIGHT BULBS, VARIOUS PRODUCTS DE HYDRA TING EQUIPMENT ;=� :I:

< V>

V> 0

en

INCLUDING,

� ca

.&,. RADIO TUBES AND FOR SUBLIMATION DRYING zo I,,

0

c ELECTRICAL CABLE. AND OF, Z<>' G>

oo

250 VACUUM TUBES FOR FOOD SPECIAL TIES, vc.. ..2

WINDINGS. ETC. FOR HIGH BLOOD PLASMA, x> ,,

o<

RADAR EQUIPMENT, PENICILLIN, VITAMINS, ........ ...

VOLTAGE SERVICE SPECIAL DRUGS, ETC. N� J-40· G>

= ...

�o

0.1 mm 100 TELEVISION SETS; AND ca"' c;

I,,

OTHER TYPES OF ·50 . l'G

v,

50 ELECTRONIC EQUIPMENT MOLECULAR DISTILLATION

& RESEARCH APPARATUS OF COMPLEX CHEMICAL

t-25

COMPOUNDS ETC.

I

I

o.o,mm 10

Note: Certain portions of this chart

5 are diagrammatic only, and special

VACUUM COATING OF modifications of these or similar

vacuum processes are often designed

2� OPTICAL PARTS AND for other than the typical ranges in·

2 dicated.

OTHER MATERIAL, ETC.

i

O.OOlmm i = I MICRON

I

OPERATING RANGES OF VACUUM PROCESSES

Most of the principal industrial processes that necessitate combinations of air, other gases, and water vapor, as shown

the use of subatmospheric pressures are listed here, to- under the three headings A, B, and C. The charts on this

gether with the typical pressure range for each one. The page and the preceding one were compiled by J. F. Plum·

processes involve the evacuation or removal of various mer, Jr., of Ingersoll-Rand Company, Phillipsburg, N. J.

Figure 6-10. Operating ranges of vacuum processes. By permission, Ingersoll-Rand Co.