Page 467 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 467

Process Safety and Pressure-Relieving Devices 433

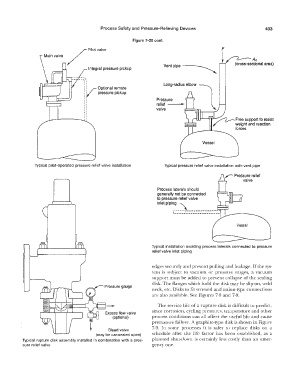

Figure 7-20 cont.

F

Ventplpe �

Long-radius elbow

Pressure

relief--�

valve

Typical pilot-operated pressure relief valve installation Typical pressure relief valve installation with vent pipe

� Pressure relief

valve

Process laterals should

generally not be connected

to pressure relief valve

piping_\

inlet -------------

\--------------------

Vessel

Typical installation avoiding process laterals connected to pressure

relief valve inlet piping

edges securely and prevent pulling and leakage. If the sys-

tem is subject to vacuum or pressure surges, a vacuum

support must be added to prevent collapse of the sealing

disk. The flanges which hold the disk may be slip-on, weld

neck, etc. Disks to fit screwed and union-type connections

are also available. See Figures 7-8 and 7-9.

- The service life of a rupture disk is difficult to predict,

Excess flow valve since corrosion, cycling pressures, temperature and other

(optional) process conditions can all affect the useful life and cause

premature failure. A graphite-type disk is shown in Figure

7-9. In some processes it is safer to replace disks on a

Bleed valve

(may be car-sealed open) schedule after the life factor has been established, as a

Typical rupture disk assembly installed in combination with a pres- planned shut-down is certainly less costly than an emer-

sure relief valve gency one.