Page 468 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 468

434 Applied Process Design for Chemical and Petrochemical Plants

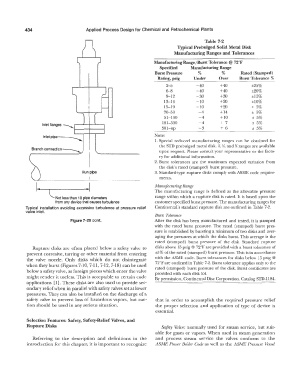

Table 7-2

Typical Prebulged Solid Metal Disk

Manufacturing Ranges and Tolerances

Manufacturing Range/Burst Tolerance @ 72°F

Specified Manufacturing Range

Burst Pressure % % Rated (Stamped)

Rating, psig Under Over Burst Tolerance %

2-5 -40 +40 ±25%

6-8 -40 +40 ±20%

9-12 -30 +30 ±15%

13-14 -10 +20 ±10%

15-19 -10 +20 ± 5%

20-50 -4 +14 ± 5%

51-100 -4 + 10 ± 5%

101-500 -4 + 7 ± 5%

Inlet flanges ----......

1-----,1-----, 501-up -3 + 6 ± 5%

Note:

Inlet pipe---....

1. Special reduced manufacturing ranges can be obtained for

the STD prebulged metal disk. ){, Y,, and X ranges are available

Branch connection �

upon request. Please consult your representative or the facto-

ry for additional information.

2. Burst tolerances are the maximum expected variation from

the disk's rated (stamped) burst pressure.

Run pipe 3. Standard-type rupture disks comply with ASME code require-

ments.

1. -I The manufacturing range is defined as the allowable pressure

Manufacturing Range

� Not less than 1 O pipe diameters range within which a rupture disk is rated. IL is based upon the

from any device that causes turbulence customer specified burst pressure. The manufacturing ranges for

Typical installation avoiding excessive turbulence at pressure relief Continental's standard rupture disk are outlined in Table 7-2.

valve inlet.

Bursi Tolerance

Figure 7-20 cont. After the disk has been manufactured and tested, it is stamped

with the rated burst pressure. The rated (stamped) burst pres-

sure is established by bursting a minimum of two disks and aver-

aging the pressures at which the disks burst. This average is the

rated (stamped) burst pressure of the disk. Standard rupture

Rupture disks are often placed below a safety valve to disks above 15 psig@ 72°F are provided with a burst tolerance of

prevent corrosive, tarring or other material from entering ±5% of the rated (stamped) burst pressure. This is in accordance

the valve nozzle. Only disks which do not disintegrate with the ASME code. Burst tolerances for disks below 15 psig @

72°F are outlined in Table 7-2. Burst tolerance applies only Lo the

when they burst (Figures 7-10, 7-11, 7-12, 7-18) can be used rated (stamped) burst pressure of the disk. Burst certificates are

below a safety valve, as foreign pieces which enter the valve provided with each disk lot.

might render it useless. This is acceptable to certain code By permission, Continental Disc Corporation, Catalog STD-1184.

applications [ 1]. These disks are also used to provide sec-

ondary relief when in parallel with safety valves set at lower

pressures. They can also be installed on the discharge of a

safety valve to prevent loss of hazardous vapors, but cau- that in order lo accomplish the required pressure relief

tion should be used in any serious situation. the proper selection and application of type of device is

essential.

Selection Features: Safety, Safety-Relief Valves, and

Rupture Disks Safety Valve: normally used for steam service, but suit-

able for gases or vapors. When used in steam generation

Referring to the description and definitions in the and process steam service the valves conform to the

introduction for this chapter, it is important to recognize ASlv1E Power Boiler Code as well as the ASJ\1E Pressure Vessel