Page 466 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 466

432 Applied Process Design for Chemical and Petrochemical Plants

r

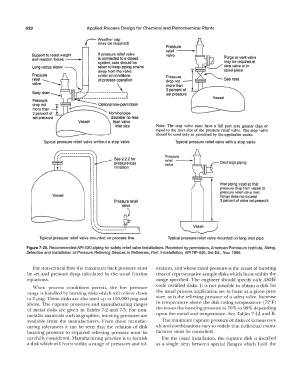

Weather cap

(may be required)

Pressure

relief

Support to resist weight If pressure relief valve valve

and reaction forces ---·, is connected to a closed

system, care should be

taken to keep piping strains

away from the valve

under all conditions Pressure

of process operation drop not

\ more than

3 percent of

---------- , I set pressure

---------------------V Vessel

Pressure � nal

drop not low-point drain

more than

3 percent of Nominal pipe

set pressure diameter no less

Vessel than valve

Inlet size Note: The stop valve must have a full port area greater than or

equal to the inlet size of the pressure relief valve. The stop valve

should be used only as permitted by the applicable codes.

Typical pressure relief valve without a stop valve Typical pressure relief valve with a stop valve

: , ,--------------, ' l See 2.2.2 for Pressure

,� pressure-loss relief Discharge piping

valve

limitation

Inlet piping sized so that

pressure drop from vessel to

pressure relief valve inlet

Vessel flange does not exceed

3 percent of valve set pressure

.

I

I

I

I

'

' ....... 1

Typical pressure relief valve mounted on process line Typical pressure relief valve mounted on long inlet pipe

Figure 7-20. Recommended APl-520 piping for safety relief valve installations. Reprinted by permission, American Petroleum Institute, Sizing,

Selection and Installation of Pressure Relieving Devices in Refineries, Part II-Installation, API RP-520, 3rd Ed., Nov. 1988.

For non-critical flow the maximum back pressure must erances, and whose rated pressure is the result of bursting

be set and pressure drop calculated by the usual friction tests of representative sample disks which burst within the

equations. range specified. The engineer should specify only ASME

code certified disks. It is not possible to obtain a disk for

When process conditions permit, the low pressure

range is handled by bursting disks which will relieve down the usual process application set to burst at a given pres-

to 2 psig. These disks are also used up to 100,000 psig and sure, as is the relieving pressure of a safety valve. Increase

above. The rupture pressures and manufacturing ranges in temperature above the disk rating temperature (72°:F)

of metal disks are given in Tables 7-2 and 7-3. For non- decreases the bursting pressure to 70% to 90% depending

metallic materials such as graphite, bursting pressures are upon the metal and temperature. See Tables 7-4A and B.

available from the manufacturers. From these manufac- The minimum rupture pressure of disks of various met-

turing tolerances it can be seen that the relation of disk als and combinations vary so widely that individual manu-

bursting pressure to required relieving pressure must be facturer must be consulted.

carefully considered. Manufacturing practice is to furnish For the usual installation, the rupture disk is installed

a disk which will burst within a range of pressures and tol- as a single item between special flanges which hold the