Page 465 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 465

Process Safety and Pressure-Relieving Devices 431

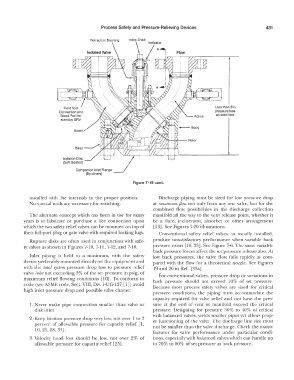

Retraction Bushing Index Shaft

Lessthan3%

Connection and pressure loss

Bleed Port for at rated flow

standbySRV

Spare

Isolation Disc

(Soft Seated)

(By others)

Figure 7-19 cont.

installed with the internals in the proper position. Discharge piping must be sized for low pressure drop

No special tools are necessary for switching. at maximum flow not only from any one valve, but for the

combined flow possibilities in the discharge collection

The alternate concept which has been in use for many manifold all the way to the vent release point, whether it

years is to fabricate or purchase a Tee connection upon be a Oare, incinerator, absorber or other arrangement

which the two safety relief valves can be mounted on top of [ 13). See Figures 7-20 illustrations.

their full-port plug or gate valve with required locking lugs. Conventional safety relief valves, as usually installed,

Rupture disks are often used in conjunction with safe- produce unsatisfactory performance when variable back

ty valves as shown in Figures 7-10, 7-l l, 7-12, and 7-18. pressure exists [10, 33). See Figure 7-6. The same variable

back pressure forces affect the set pressure release also. At

Inlet piping is held to a minimum, with the safety low back pressures, the valve flow falls rapidly as com-

device preferably mounted directly on the equipment and pared with the flow for a theoretical nozzle. See Figures

with the total system pressure drop loss to pressure relief 19 and 20 in Ref. [33a].

valve inlet not exceeding 3% of the set pressure in psig, of For conventional valves, pressure drop or variations in

maximum relief flowing conditions [JO]. To conform to back pressure should not exceed 10% of set pressure.

code (see ASME code, Sect, VIII, Div. l-UG-127 [l]) avoid Because most process safety valves are sized for critical

high inlet pressure drop and possible valve chatter:

pressure conditions, the piping must accommodate the

capacity required for valve relief and not have the pres-

1. Never make pipe connection smaller than valve or sure at the end of vent or manifold exceed the critical

disk inlet pressure. Designing for pressure 30% to 40% of critical

with balanced valves, yields smaller pipes yet allows prop-

2. Keep friction pressure drop very low, not over I to 2 er functioning of the valve. The discharge line size must

percent of allowable pressure for capacity relief [l, not be smaller than the valve discharge. Check the manu-

10, 25, 28, 33].

facturer for valve performance under particular condi-

3. Velocity head loss should be low, not over 2% of tions, especially with balanced valves which can handle up

allowable pressure for capacity relief [25]. to 70% to 80% of set pressure as back pressure.