Page 512 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 512

478 Applied Process Design for Chemical and Petrochemical Plants

where Ve = cubic feet of free air /hr from Table 7-17 or Equa- Due to the importance of complying with all standards

tion 7-49 for any fluid. and regulations, and the necessary reduction in detail in

L = latent heat of vaporization of liquid, BTU /lb such a summary as presented here, it is recommended that

M = molecular weight of liquid the ASME, API and NFPA standards and codes be consult-

ed for final design detail and installation conformity.

T = temperature of the relief vapor, R

0

Refer to API-2000 [26] for recommendation regarding

The vent size may be determined based on the pres- installation requirements. Tank venting equipment capac-

sure that the tank can safely withstand [26]. ities are expressed as free air /hour. For handling other

fluids besides hexane or gasoline, use equation for V'c

The code [26] allows a credit or reduction of required

emergency venting for specific conditions. The final total (Equation 7-48) to convert to equivalent free air flow.

emergency venting requirements may be determined as:

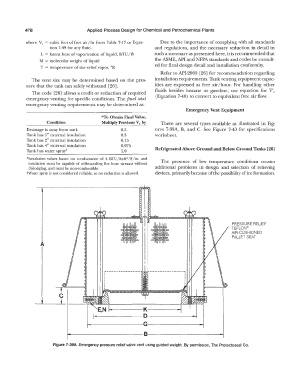

Emergency Vent Equipment

*To Obtain Final Value,

Condition Multiply Previous Ve by There are several types available as illustrated in Fig-

Drainage is away from tank 0.5 ures 7-39A, B, and C. See Figure 7-40 for specifications

Tank has I" external insulation 0.3 worksheet.

Tank has 2" external insulation 0.15

Tank has 4" external insulation 0.075

Tank has water spray" 1.0 Refrigerated Above Ground and Below Ground Tanks [26]

*Insulation values based on conductance of 4 BTU/hr-ft 2 -°F/in. and The presence of low temperature conditions creates

insulation must be capable of withstanding fire hose streams without

dislodging, and must be non-combustible. additional problems in design and selection of relieving

+Water spray is not considered reliable, so no reduction is allowed . devices, primarily because of the possibility of ice formation.

•• PRESSURE RELIEF

TEFLON®

AIR-CUSHIONED

PALLET SEAT

A

,--------------, r--------------,

I I I I

I I I I

I I I I

I I I I

I I

I I I

i--------K----------

i----------�0-------

..-.-----------�-------

-----------------�B�---------------'-

Figure 7-39A. Emergency pressure relief valve vent using guided weight. By permission, The Protectoseal Co.