Page 513 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 513

Applied Process Design 479

3. Control valve failure

4. Vapor displacement during filling

5. Withdrawal of stored liquid at maximum rate (refer

to section on non-refrigerated tanks)

6. Withdrawal of vapor at maximum compressor suc-

tion rate.

7. Drop of barometric pressure.

Under some circumstances it may not be appropriate

Figure 7-39A. Continued. to allow air to enter (inbreathe) into the tank, then the

use of some other inert gas, such as nitrogen or natural

gas, is acceptable on a pressure control basis; however,

The capacity of pressure-vacuum devices for a tank are this cannot take the place of a vacuum relieving device to

to be determined at 110% of their "start to discharge" allow air to enter under a final emergency condition.

pressure. Except for emergency pressure relieving because

of fire, the capacity may be determined at 120% [26].

Normal conditions Emergency Venting far Fire Exposure

At least the following conditions or some combination For refrigerated tanks the total venting requirement is

must be considered in establishing the normal pressure- the value determined from Table 7-17, multiplied by the

vacuum relief capacity requirements [26]: environment factor F from Table 7-18. For tanks greater

than 2,800 ft. 2 exposed wetted surface, use the venting

1. Loss of refrigeration formula for Ve (Equation 7-49). Do not apply the factors

2. Liquid overfilling from Table 7-18.

�'

It ''f

I ,,,p,7

J

t: "-�t''i

J,,, ... /,�-'?;,,

,, t, fi'r/--1-'

�

/1,'.1•1 ' \

I 1, /1,1

/I ,' 1/d

JI ,I '11/

1 1 11 1·,

1/ ,'! 1/,)

,, ,,,,,, + 0

/1 I ,,,,,, '11 750 _ 50

ff l{t/

\

r II /t •. Jiii I I. I I -------

I' //II//

/1

I I I I

,,

,I II/

/I

JI

I

-

•

I

A FIL I E

l : -N

ij

: :

I I I

I. K J

'

c

B

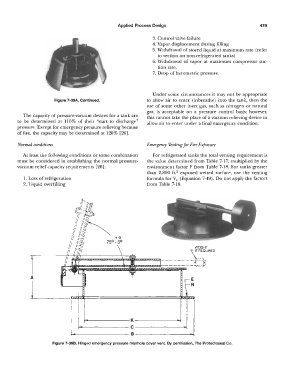

Figure 7-398. Hinged emergency pressure manhole cover vent. By permission, The Protectoseal Co.