Page 515 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 515

Applied Process Design 481

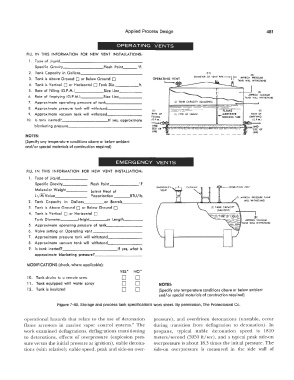

OPERATING VENTS

FILL IN THIS INFORMATION FOR NEW VENT INSTALLATIONS:

1. Type of Liquid

Specific Gravity_ Flash Point °F.

2. Tank Capacity in Gallons _ (11) (8)

3. Tank is Above Ground D or Below Ground D DIAMETER OF VENT PIPE---+ 11- APPROX. PRESSURE

fANk Will WITHSTAND

4. Tank is Vertical O or Horizontal D Tank Dia. ft.

5. Rate of Filling (G.P.M.) Size Line _

6. Rote of tmptying (G.P.M.) Size Line _

7. Approximate operating pressure of tank _

8. Approximate pressure tonk will withstand, _

(5) (6)

9. Approximate vacuum tonk will withstand _ RATE Of RATE Of

FILLING EMPTYING

10. Is tank inerted? If yes, approximate (G.P.M.J (G.P.M.J

blanketing pressure _

��,ml,""""�,i,l\,f;.,,,-m,:?;i,,�,Jm����""'�'"""'����rof

LINE

NOTES:

(Specify any rempercture conditions above or below ambient

and/ ar special materials of construction required)

EMERGENCY VENTS

FILL IN THIS INFORMATION FOR NEW VENT INSTALLATION:

l. Type of Liquid

Specific Gravity_ Flash Point °F

r-OPERATING VENT

Molecular Weight Latent Heat of

L\!MValue Vaporization BTU/lb.

(71 APPROX. PRESSURE TANK

2. Tonk Capacity in: Gallons or Barrels. _ Will WITHSTAND

3. Tank is Above Ground D or Below Ground D

4. Tank is Vertical [].or Horizontal O

(Bl

Tank Diameter Height or Length _ APPROX. VACUUM

TANK Wilt WITHSTAND

5. Approximate operating pressure of tank _

6. Valve setting on Operating vent.-----------

7. Approximate pressure tank will withstand _

8. Approximate vacuum tank wili withstand _

9. Is tank inerted? lf yes, what is

approximate blanketing pressure? _

MODIFICATIONS [cheek, where applicable):

YEs· No·

10. Tank drains tc a remote area D D

l l. Tank equipped with water spray D D NOTES:

1 2. Tank is insulated D D (Specify any temperature conditions above or below ambient

and/ or special materials of construction required)

Figure 7-40. Storage and process tank specifications work sheet. By pennission, The Protectoseal Co.

operational hazards that relate to the use of detonation pressure), and overdriven detonations (unstable, occur

flame arrestors in marine vapor control systems." The during transition from deflagration to detonation). In

work examined deflagrations, deflagrations transitioning propane, typical stable detonation speed is 1810

to detonations, effects of overpressure (explosion pres- meters/ second (5950 ft/ sec), and a typical peak side-on

sure versus the initial pressure al ignition), stable detona- overpressure is about 18.3 times the initial pressure. The

tions (with relatively stable speed, peak and side-on over- side-on overpressure is measured in the side wall of