Page 545 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 545

Applied Process Design 511

Vent Release Pressure Maximum Pressure During Venting

11 I I I

.,r--Pstat =0.1 bar ga P,ed = 0.2 bar ga -------. I �

-------. -,

/ ,--Pstat =0.2 bar ga

P,ed = 0.4 bar ga

.,

' ilv v / // ,-- P,tat = 0.5 bar ga P,ed = 0.6 bar ga -------. -, " � r.. / i.,,"" �� �

�""'

'

/.,

"

P,cd = 0.8 bar ga -------. <,

/

"\.[\

\ �

.... �

v

r.. '"'�

' \ .� \. / ..,., v P,ed = 1 .0 bar ga � <, ' "" // L,., i, ... �

��

'\ '\.'<..., � ii P,ed = 1 .5 bar ga -------. '" ' "'\ Y .. -: � � , ... ... �

r..

r..

'\.'� P,ed = 2.0 bar ga "'\ ," � "' ' .» � / vv ;�

r....-�

I

i..,

// I/I,,'

'\. ' � I <, r-, >"" r..,.. � /

i'i'I v �� :�/ ..-r

l'l.i'.. / ); /

� i\ v � .... '//

';

...

' � // � r- / ,.; �/

/ /

"

i\ �

�

" I\.\ l'-.. // ,.,.; /h -> / / ,.,.;

....

.,

.'\. '\.

'\

V/ /

/

;

...

v

; //

/

I "'\ / v v/ '/ / j I i

.,/ .... � �

'\ ,r-..

�

/

� v

' " �\ , /: , v" � , I I I

�' v..o: v v .,,,," l i .

�

' � v/

' " � v v !

�/

v

' "r'\. '\ I

I 'I\.'\.'\ v

I '\. '

i '

50 10 0.1 10 100 1000

----Vent Area, m 2 Vessel Volume, m 3 .,.

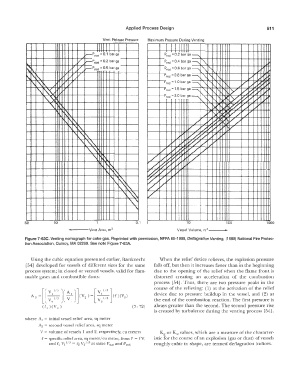

Figure 7-63C. Venting nomograph for coke gas. Reprinted with permission, NFPA 68-1988, Deflagration Venting, (1988) National Fire Protec-

tion Association, Quincy, MA 02269. See note Figure 7-63A.

Using the cubic equation presented earlier, Bartknecht When the relief device relieves, the explosion pressure

[54] developed for vessels of different sizes for the same falls off, but then it increases faster than in the beginning

process system; in closed or vented vessels, valid for flam- due to the opening of the relief when the flame front is

mable gases and combustible dusts: distorted creating an acceleration of the combustion

process [54]. Thus, there are two pressure peaks in the

course of the relieving: ( 1) at the activation of the relief

device due to pressure buildup in the vessel, and (2) at

the end of the combustion reaction. The first pressure is

always greater than the second. The second pressure rise

is created by turbulence during the venting process [54].

where A 1 = initial vessel relief area, sq meter

A2 = second vessel relief area, sq meter

V = volume of vessels 1 and 2, respectively, cu meters K" or Kst values, which are a measure of the character-

f = specific relief area, sq meter/ cu meter, from F = I V, istic for the course of an explosion (gas or dust) of vessels

and r, V, 113 = f2 \12113 at same P, 1 a 1 and P,ect roughly cubic in shape, are termed deflagratiou indices.