Page 561 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 561

Applied Process Design 527

cle diameter [ (2) (inlet pipe)]. Thus, the cross-section

area of vapor space A. with equivalent diameter S should

Latu be at least [ (2) (ap)] where ap is the cross-sectional area of

the inlet pipe [33]. To avoid bubble burst slugging, this

author suggests that the cross-sectional area of S be calcu-

lated to have a vapor velocity of less than the entrainment

EM!

ll•ra velocity for a mist sized liquid particle, or that the vapor

at.ck

b¥o=• area be approximately one-third the cross-section area of

the diameter of the horizontal drum. For a vertical drum,

Ref. [33] recommends that the vapor disengaging height

K�

be three feet.

When vacuum can form in the system due to condens-

ing/ cooling hot vapor entering, the seal drum liquid vol-

ume and possibly the seal drum diameter /length must be

,._....... adjusted to maintain a seal when/if the seal fluid is drawn

up into the inlet piping. A vacuum seal leg should be pro-

----- _,.,_, vided on the inlet 1.2 times the expected equivalent vacu-

Figure 7-69. Illustration of one of many collection arrangements for um height in order to maintain a seal.

process flow and/or relief valve discharge collections to relieve to The following design points should be considered:

one or more plant flare stacks. By permission, Livingston, D. D., Oil

& Gas Jour., Apr. 28, 1980. • Provide liquid low level alarms to prevent loss of liq-

uid by evaporation, entrainment, leaks, or failure of

the makeup liquid system.

12 inches to 18 inches. This would be a segment (hori-

zontal vessel) of a circle (see Appendix Table 24). Ref. • Use a sealing liquid that has a relatively low vapor

[33] recommends that the cross section area of the vapor pressure, and is not readily combustible, and will not

space above the liquid be at least equivalent to that of a cir- readily freeze. Quite often glycol or mixtures are

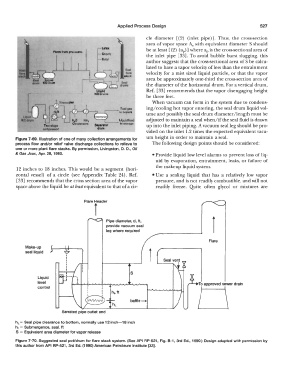

Pipe diameter, d, ft,

provide vacuum seal

leg where required

Flare

Make-up

r

seal liquid

.,

-,--- s

I

I

Liquid

level

control

baffle-

Serrated pipe outlet end

hL = Seal pipe clearance to bottom, normally use 12 inch-18 inch

h 1 = Submergence, seal, ft

S = Equivalent area diameter for vapor release

Figure 7-70. Suggested seal poVdrum for flare stack system. (See API RP-521, Fig. 8-1, 3rd Ed., 1990.) Design adapted with permission by

this author from API RP-521, 3rd Ed. (1990) American Petroleum Institute (33].