Page 336 - Fluid Fitting 2018_extended

P. 336

HIGH QUALITY PRODUCTS EXCELLENCE IN SERVICE

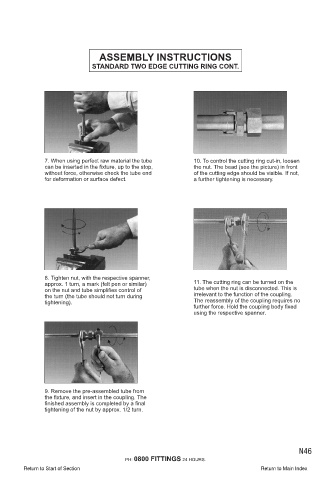

ASSEMBLY INSTRUCTIONS

STANDARD TWO EDGE CUTTING RING CONT.

7. When using perfect raw material the tube 10. To control the cutting ring cut-in, loosen

can be inserted in the fixture, up to the stop, the nut. The bead (see the picture) in front

without force, otherwise check the tube end of the cutting edge should be visible. If not,

for deformation or surface defect. a further tightening is necessary.

8. Tighten nut, with the respective spanner,

approx. 1 turn, a mark (felt pen or similar) 11. The cutting ring can be turned on the

on the nut and tube simplifies control of tube when the nut is disconnected. This is

the turn (the tube should not turn during irrelevant to the function of the coupling.

tightening). The reassembly of the coupling requires no

further force. Hold the coupling body fixed

using the respective spanner.

9. Remove the pre-assembled tube from

the fixture, and insert in the coupling. The

finished assembly is completed by a final

tightening of the nut by approx. 1/2 turn.

PH: 0800 FITTINGS 24 HOURS. N46

vii

PH: 0800 FITTINGS 24 HOURS.

Return to Start of Section Return to Main Index