Page 35 - E BOOK ENGINE MECHANICAL M2

P. 35

5. SERVICE POINTS OF 4B1 ENGINE COMPONENT

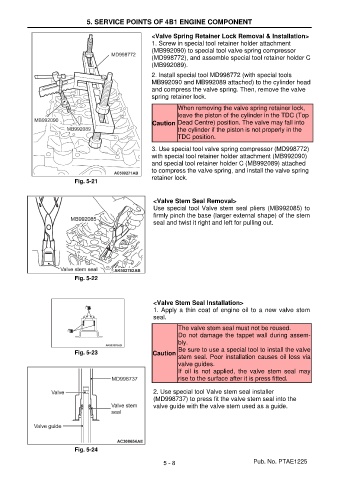

<Valve Spring Retainer Lock Removal & Installation>

1. Screw in special tool retainer holder attachment

(MB992090) to special tool valve spring compressor

(MD998772), and assemble special tool retainer holder C

(MB992089).

2. Install special tool MD998772 (with special tools

MB992090 and MB992089 attached) to the cylinder head

and compress the valve spring. Then, remove the valve

spring retainer lock.

When removing the valve spring retainer lock,

leave the piston of the cylinder in the TDC (Top

Caution Dead Centre) position. The valve may fall into

the cylinder if the piston is not properly in the

TDC position.

3. Use special tool valve spring compressor (MD998772)

with special tool retainer holder attachment (MB992090)

and special tool retainer holder C (MB992089) attached

to compress the valve spring, and install the valve spring

retainer lock.

Fig. 5-21

<Valve Stem Seal Removal>

Use special tool Valve stem seal pliers (MB992085) to

firmly pinch the base (larger external shape) of the stem

seal and twist it right and left for pulling out.

Fig. 5-22

<Valve Stem Seal Installation>

1. Apply a thin coat of engine oil to a new valve stem

seal.

The valve stem seal must not be reused.

Do not damage the tappet wall during assem-

bly.

Be sure to use a special tool to install the valve

Fig. 5-23 Caution

stem seal. Poor installation causes oil loss via

valve guides.

If oil is not applied, the valve stem seal may

rise to the surface after it is press fitted.

2. Use special tool Valve stem seal installer

(MD998737) to press fit the valve stem seal into the

valve guide with the valve stem used as a guide.

Fig. 5-24

5 - 8 Pub. No. PTAE1225