Page 655 - CarrLaneCatalog_2019ed-c.pdf

P. 655

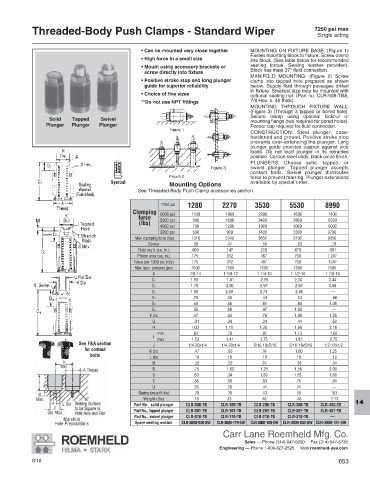

Threaded-Body Push Clamps - Standard Wiper 7250 psi max

Single acting

• Can be mounted very close together MOUNTING ON FIXTURE BASE: (Figure 1)

Fasten mounting block to fixture. Screw clamp

• High force in a small size into block. (See table below for recommended

• Mount using accessory brackets or seating torque. Sealing washer provided).

screw directly into fixture Block has male 37° fluid connection.

MANIFOLD MOUNTING: (Figure 2) Screw

• Positive stroke stop and long plunger clamp into tapped hole prepared as shown

guide for superior reliability below. Supply fluid through passages drilled

in fixture. Smallest size may be mounted with

• Choice of five sizes optional sealing nut. (Part no. CLR-508-TBA,

**Do not use NPT fittings 7/8 Hex. x. 46 thick).

MOUNTING THROUGH FIXTURE WALL:

(Figure 3) (Through a tapped or bored hole).

Secure clamp using optional locknut or

Solid Tapped Swivel

mounting flange (two required for bored holes).

Plunger Plunger Plunger Feeder cap required for fluid connection.

CONSTRUCTION: Steel plunger, case-

hardened and ground. Positive stroke stop

prevents over-extending the plunger. Long

plunger guide provides support against side

loads. Do not load plunger in its retracted

position. Carbon steel body, black oxide finish.

PLUNGERS: Choose solid, tapped, or

swivel plunger. Tapped plunger accepts

contact bolts. Swivel plunger distributes

force to prevent marring. Plunger extensions

Mounting Options available by special order.

See Threaded-Body Push Clamp accessories section

7250 psi

1280 2270 3530 5530 8990

Clamping

6000 psi 1100 1900 2900 4500 7400

force

5000 psi 900 1600 2400 3800 6200

(lbs)

4000 psi 700 1200 1900 3000 5000

3000 psi 500 900 1400 2300 3700

Max. clamping force (lbs) 1310 2340 3650 5700 9350

Stroke .38 .47 .59 .63 .78

Fluid req’d (cu. in.) .069 .147 .228 .479 .981

Piston area (sq. in.) .175 .312 .487 .760 1.247

Force per 1000 psi (lbs) 175 312 487 760 1247

Max. oper. pressure (psi) 7500 7500 7500 7500 7500

A 7/8-14 1-1/8-12 1-1/4-16 1-1/2-16 1-7/8-16

C1 1.50 1.81 2.19 2.34 3.44

C2 1.78 2.06 2.59 2.69 3.88

C3 1.80 2.09 2.73 2.86 —

D1 .28 .38 .44 .53 .66

D2 .56 .66 .81 .88 1.09

D3 .56 .69 . 97 1.05 —

F dia .47 .63 .78 1.00 1.25

G .31 .34 .34 .44 .50

H 1.00 1.19 1.38 1.69 2.16

min. .63 .78 .97 1.13 1.66

I

max 1.53 1.41 1.75 1.81 2.75

See F&A section

J 1/4-20x1/4 1/4-20x1/4 5/16-18x5/16 5/16-18x5/16 1/2-13x1/2

for contact

K dia .47 .63 .78 1.00 1.25

bolts L dia .19 .19 .19 .19 .19

M .22 .22 .25 .28 .34

R .75 1.00 1.25 1.56 2.00

S .69 .94 1.69 1.25 1.69

T .38 .50 .63 .75 .94

U .28 .28 .41 .41 —

Seating torque (ft.-lbs) 29 36 43 58 163

Weight (lbs) .18 .33 .48 .48 2.13

Part No., solid plunger CLR-000-TB CLR-100-TB CLR-200-TB CLR-300-TB CLR-400-TB 14

Part No., tapped plunger CLR-001-TB CLR-101-TB CLR-201-TB CLR-301-TB CLR-401-TB

Part No., swivel plunger CLR-010-TB CLR-110-TB CLR-210-TB CLR-310-TB —

Manifold

Hole Preparations Spare sealing washer CLR-3000-840-SW CLR-3000-179-SW CLR-3000-180-SW CLR-3000-843-SW CLR-3000-181-SW

Carr Lane Roemheld Mfg. Co.

Sales — Phone (314) 647-6200 Fax (314) 647-5736

Engineering — Phone 1-800-827-2526 Web roemheld-usa.com

8/18 653